Water companies have set out 2025-2030 leakage ambitions that, if achieved, would put them among the top five performing countries in Europe. With higher operational costs and resource challenges to factor in, the supply chain can offer a more efficient route to success, writes Barbara Hathaway, leakage technology leader, Ovarro.

Barbara Hathaway, leakage technology leader, Ovarro

Ambitious leakage reduction plans put forward by water companies in England and Wales aim to cut leakage by over a quarter by 2030, compared with the start of the decade.

The proposals are a key aspect of water companies’ 2025-2030 businesses plans, which, if approved by regulator Ofwat, would deliver the largest ever investment in the sector.

However, the transition from asset management periods – AMP7 to AMP8 – comes with more immediate challenges. Water companies must deliver a short sharp improvement by 2025, following Ofwat’s 2022-2023 performance report, which found the majority of companies had under-performed in leakage and other areas.

Ovarro works in partnership with UK water companies and understands they have been impacted by rising operational costs and labour market challenges, in the same way as all businesses. Suppliers should now be positioning their offerings to drive increased productivity and efficiency for water companies – how can they help their clients achieve a better outcome with the same resources or less?

As-a-service solutions, such as Ovarro’s LeakNavigator, are becoming widely available in water and can go a long way towards solving resource issues. The models are subscription-based, with infrastructure that is entirely managed by an external supplier.

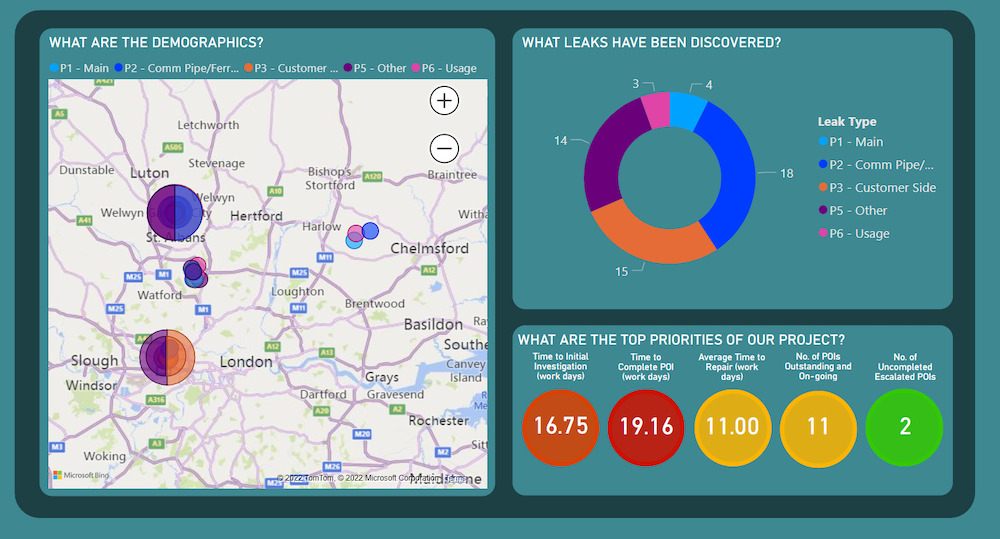

LeakNavigator takes complete ownership of the upfront logger deployment planning and day-to-day data analysis, directly alerting technicians to points of interest. Having the entire analytics process managed by a supplier, frees up skilled leakage technicians to target their time on pinpointing leaks with a very high likelihood of success.

A reduction in non-revenue water loss and of course, reducing the likelihood of regulatory penalties for missed targets, are also efficiencies to be gained.

Following its launch in February 2023, LeakNavigator is recording a combined performance increase of 20-25% in total leaks found, plus a 30% reduction in lost field time through false positives and a point-of-interest-to-leak conversion rate of over 85%. The system is a tangible example of how closer working with suppliers can bring more efficient outcomes.

Another example was the development of the Enigma3hyQ leak logger, in partnership with Anglian Water, to help solve the challenge of detecting leaks on plastic pipes. This was historically, one of the industry’s biggest challenges as plastic pipes do not propagate leak noise in the same way as metal pipes .

Enigma3hyQ loggers use immersed hydrophone sensors that ‘listen’ to sound waves transmitted inside the pipe to pinpoint leaks and can pick up vibrations over longer distances. This means they are valuable for use on wider diameter pipes and over longer distances for both metallic and plastic pipes.

Technology has a critical role to play in improving performance and suppliers are ready to support with solutions that can be implemented quickly. I would encourage all water companies to talk to their technology providers about what their outcomes should be and their strategies for getting there.

Working collaboratively with suppliers will help move towards those outcomes in an efficient and cost-effective way. Early engagement will also influence suppliers’ own product roadmaps, achieving better outcomes for all.

Barbara Hathaway will present on the subject ‘moving leakage technology forward’ at Aquatech Amsterdam on 6 November 2023 at 15.30