Thordon Bearings pioneering polymer bearing technology is gaining traction in Vietnam’s hydropower market, following the performance success of its self-lubricating bearings retrofitted to five turbines at the Son La Hydropower plant.

Thordon’s wicket gate and linkage bearings have been in continuous use for four years and were installed when the company was asked to provide an alternative to a competing system, some parts of which had failed after just two years under the intensive conditions at the dam.

Having entered service in December 2012, the Son La Hydropower project is situated on the Ðà River in It Ong, Muong La District, Son La Province and is the largest hydropower dam in Southeast Asia.

With a length of 961.6m (3300ft), the concrete gravity dam features a crest height of 228m (748ft), bottom width of 105m (304ft) and crest width of 10m (33ft). Total installed capacity of 2,400MW and average annual electricity output of over 10 billion kWh by way of six Francis-type turbines.

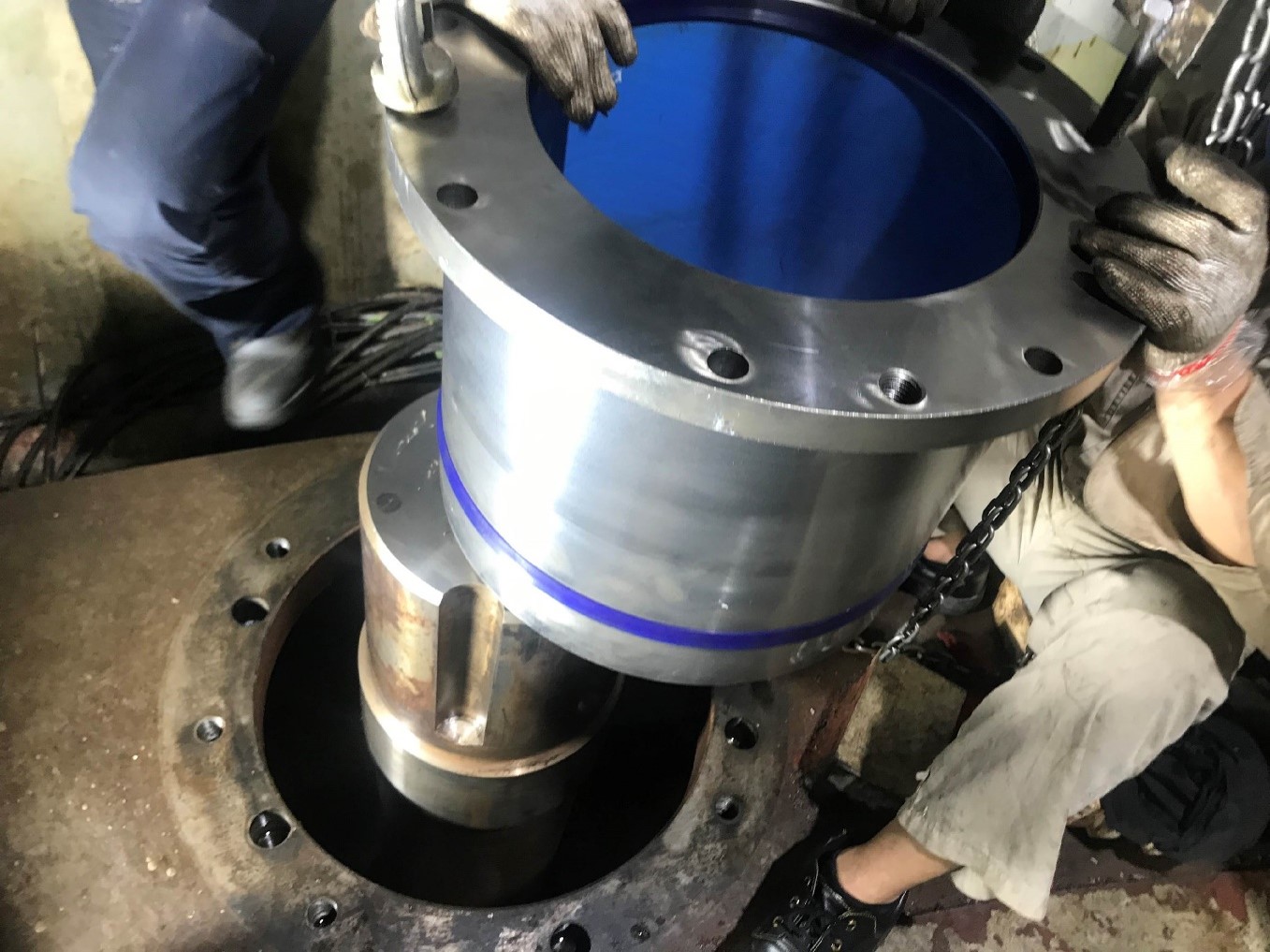

Delta Marine & Industries, Thordon’s authorized distributor in Vietnam, worked with end user Vietnam Electricity (EVN) to choose suitable replacements for the original metal polymer lined bearing. The refit included ThorPlas-Blue wicket gate and linkage bearings with washers, Thordon SXL operating ring wear pads, Thordon Thor-Flex wicket gate seals, and SXL upper and lower gate seal.

Thordon’s hydro turbine bearings and seals are designed to efficiently replace worn components such as those at Son La, said Johnny Dao, Managing Director, Delta Marine & Industries. “Thordon’s grease-free bearing products for hydropower installation combine a very low coefficient of friction with low wear in abrasive water environment and high resistance to shock loading and vibration. They offer high pressure performance and resilience, as well as extremely long wear life.”

The original material was delaminated, with severe wear to the bushing surface. “Finding a sustainable solution was critical for the client due to the original parts having failed so soon after entering service,” said Axel Swanson, Thordon Bearings’ Business Development Manager – Hydro, Pump & Industrial.

“It was important to them that our products could perform well in the unique challenges of the application, as the high shock load of the existing wicket gates’ operating ring that had destroyed the existing wear pads. The original seals had also hardened after a few years, leading to cracks and leaks.”

Thordon’s solution to these problems involved using Thor-Flex and Thordon SXL for the lower and upper gate seals, and SXL for the operating ring wear pads. Thorseals were used in place of the existing rubber seals and ThorPlas-Blue for the intermediate bearing.

The Son La Hydropower plant’s new bearings and pads have been in safe and stable operation for four years, and Delta Marine & Industries is now looking forward to installing Thordon products across the dam’s remaining turbines.