PPG has expanded its portfolio of spiral-wound filter elements with the launch of a new ultrafiltration (UF) antifouling membrane designed specifically for difficult-to-treat industrial wastewater applications.

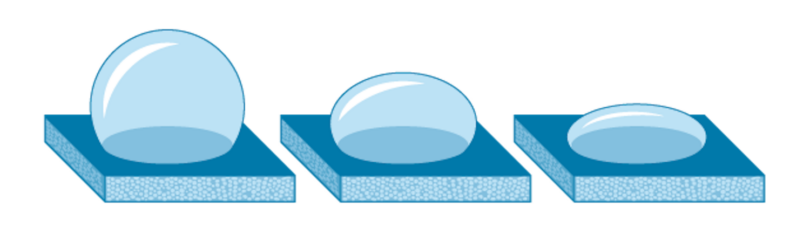

The new UF membrane is engineered for high-performance water purification in environments containing oily waste and other complex contaminants, enabling industries to safely and economically reuse or dispose of wastewater. The membrane features a super-hydrophobic surface that effectively resists fouling from oil, grease and other hard-to-remove materials, reducing maintenance demands and extending operational lifespan.

According to Lisa Walters, Strategic Market Manager, Filtration, Specialty Products at PPG, “Our customers face increasing pressure to reduce costs and operate more sustainably. This new membrane delivers on both fronts, providing exceptional performance in oily, high-fouling environments such as bilge water treatment, while reducing maintenance requirements and extending membrane life. It also supports cost-effective water reuse, helping customers reduce reliance on external water supplies but also supports efforts to address global water scarcity challenges.”

Unlike other UF and microfiltration (MF) membranes on the market, PPG’s entire membrane range is manufactured using a proprietary composite material that does not contain intentionally added polyfluoroalkyl substances (PFAS). This sustainable design helps industries align with stricter global environmental regulations and corporate sustainability goals.

Applications for the new UF membrane include:

- Offshore and onshore oil–water separation

- Dry dock and in-water marine ship treatment

- Industrial process water and wastewater treatment

- Automotive and industrial paint lines

- Greywater recovery and treatment

The new membrane will be produced at PPG’s Barberton, Ohio facility, where the company has invested in advanced manufacturing equipment to meet growing market demand for sustainable filtration technologies.

PPG’s high-performance MF and UF membranes deliver higher throughput rates than conventional systems, reducing the number of filters and floor space required for industrial water recovery. These efficiencies contribute to lower operating costs and improved durability, ensuring long-term reliability for industrial users.

For more information, visit the official PPG Filtration page at www.ppg.com/filtration.