The treatment of wastewater is an energy-intensive and high-cost process worldwide; however, it is vital for maintaining water infrastructure and protecting public health. Energy is demanded at all stages of the treatment process and beyond, regarding the production and transport of chemicals as well as ongoing maintenance costs. Wastewater treatment 2020-21 is set against a backdrop of increasingly tight regulations regarding discharge limits and a rising cost of energy. Optimisation and energy saving are the goals now pursued by water utilities across the globe as the need to meet the increasing demand for high-quality effluent competes with the immense costs associated with such intensive.

In many scenarios, treatment infrastructure is already well established and unlikely to change due to the sizeable cost and logistical challenges involved. Instead, attention has turned to how existing processes can be improved upon using new and innovative technologies to re-frame existing challenges.

One such innovation has involved fluorescence spectroscopy which works on the principle of intrinsic fluorescence or organic matter, in that different types of organic matter fluoresce at known wavelengths. The ability to take fluorescence spectroscopy technology into the field has been a recent and exciting innovation that has already been tested in a variety of wastewater scenarios (Bridgeman et al., 2012; Cohen et al., 2014; Carstea et al., 2016; Goffin et al., 2018). The potential of the technology is almost unquantifiable as it can provide a highly accurate, real-time proxy for DOM dynamics in wastewater.

Proteus Instruments developed the Proteus multiprobe and an algorithm that relates the raw fluorescence signal to Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD), among others (Proteus Instruments, 2020). BOD and COD were previously parameters that could only be measured using the traditional laboratory method. The BOD laboratory test takes five days, excluding time for sample collection, transport and results returned. In addition, it is prone to a substantial cumulative error due to the many stages involved in the process, therefore making it totally impractical for process monitoring and control.

The initial industry testing of the Proteus multiprobe in wastewater showed its useful application as a compliance monitor at the final effluent discharge tank however, the full scope of application can go far beyond that. It was also installed at a Pre-Settlement Tank (PST) and used to monitor BOD and COD in the wastewater passing through. This revealed how Proteus could be instrumental in monitoring compliance and overall reduction in BOD/COD levels as the water passes through the treatment process. Given the wealth of data that could be collected at the beginning of the treatment process, Proteus has now become an option for feed-forward and feedback control.

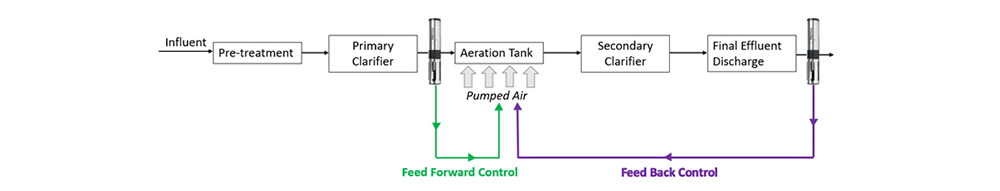

Figure 1 -Proteus being used at a WWTWFeedback and feedforward control are both popular systems that are becoming more widely utilised to boost efficiency in wastewater treatment. Feedback control works on the basis that there is a defined control variable input to the ‘controller’ and actions are taken based on the difference between the measured value and the optimum value (Reiger et al., 2014). In essence, the data recorded is used to make decisions retrospectively. Feedforward control is an attempt to avoid the error occurring in the first place with a process disturbance being measured and then entered into a predictive model which forecasts how the system should react (Reiger et al., 2014); appropriate action can then be taken to limit the effects of the disturbance before it happens.

Figure 2 – Example of Proteus being installed for feed forward and feedback control for the aeration process

The Activated Sludge Process (ASP) is one of the most energy-intensive processes in modern wastewater treatment. The aeration and pump support system alone can account for over 70% of electricity consumption at WWTW (Asadi et al., 2016). Aeration alone can account for 45-75% of total energy cost for WWTWs (Longo et al., 2016; Gikas et al., 2017). ASP lanes contain a mixture of both wastewater and bacteria; the bacteria feed on the polluting substances in the wastewater thereby removing them from the water.

To sustain the bacterial communities, the ASP lanes use blowers which continually aerate the water, ensuring the biomass is maintained in suspension and able to respire. Naturally, the more polluted the water is the more oxygen is required to aerate the water and keep the balance of organisms. Aeration must regulate a precise equilibrium between the bacteria and the wastewater; bacteria are continually recirculated using pumps and can be removed if they become excessive in number.

To maintain the biomass, many parameters are monitored daily to monitor both biomass health and composition. Ammonia, Dissolved Oxygen (DO) and Total Suspended Solids (TSS) are the most commonly measure parameters in all ASP lanes. Ammonia is a key parameter in wastewater that has a reduction and compliance limit. Ammonia is removed during the ASP by autotrophic bacteria completing biological nitrification. As with BOD reduction, ammonia conversion relies upon the bacteria biomass level to be maintained as it relies on specific autotrophic bacteria for both stages; the conversion of Ammonia to nitrite and the conversion of nitrite to nitrate (Reiger et al., 2014).

Figure 3 – A typical set of ASP lanes

Image sourced from https://deltawater.net/reinventing-the-role-of-medical-affairs-2/

Ammonia can be used for both feed-forward and feedback control of the treatment process, from both a limiting aeration perspective and for reducing ammonia peaks (Reiger et al., 2014). While ammonia has undoubtedly become an asset to wastewater treatment in recent years, it can only go so far to increasing optimisation and efficiency. Ammonia is effectively being used as a proxy because more specific measures were unable to be measured at the required frequency.

Ammonia and BOD removal are intrinsically linked as the breakdown of Ammonia provides the proteins which are used by the heterotrophic bacteria to both break down food and BOD. If conditions become ammonia limited, BOD removal becomes linear as opposed to logarithmic or exponential removal which is seen under non-limited nutrient conditions (EBS, 2020). The amount of ammonia required to remove the BOD in-line with consent limits varies depending on the content of the wastewater. Wastewater content and loadings show considerable variation on different timescales e.g., diurnal, seasonal etc. While ammonia can act as a good indicator of bacterial quality, it doesn’t provide as much detail as BOD.

In comparison to DO, BOD is a far superior measure as it is much closer to replicating the natural oxidative and recovery conditions in natural systems; this instantly provides more context as to the state of the bacterial community than DO. The maximum BOD discharge in the UK is 50 mg/l with a BOD reduction target of 70-90% from original influent; the discharge limit can be adjusted based on individual site PE (EA, 2019). Regulations are tight and non-compliances are costly as well as dangerous to the surrounding environment. By monitoring BOD in real-time throughout the treatment process, the likelihood of meeting the compliances increases. It is also an excellent diagnosis tool to detect instantly if there is a problem developing within the treatment process.

Currently, parameters such as ammonia and DO have been discussed and employed in both methods of control (Reiger et al., 2014). While the data can be undoubtedly useful in refining processes and starting to boost efficiency, the data isn’t nuanced enough to reach maximum efficiency. As previously mentioned, BOD has incredible power as a parameter that has previously been held back by the laborious and lengthy testing method; however, BOD in real-time for process control is a game-changer.

To illustrate the case, data was collected over a 61-day period in February-April 2018 using a Proteus multiprobe at a large WWTW (PE 93,500). BOD and COD was monitored alongside a variety of other parameters in 5-minute intervals and then daily averages were calculated.

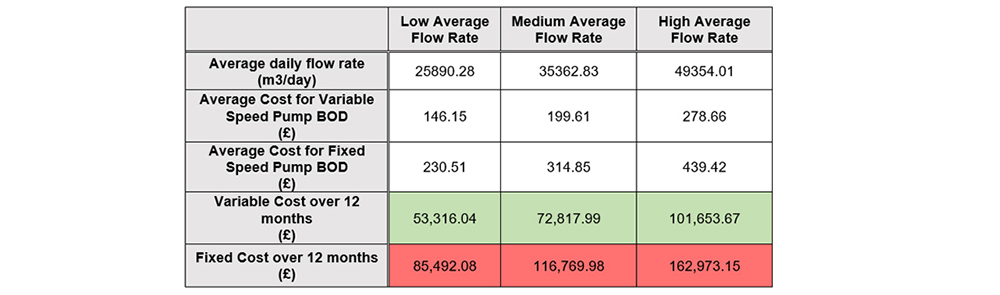

This data was then combined with typical data for ASP process formulae and coefficients to calculate the oxygen requirement for the observed BOD value at three different flow rates (Lenntech, 2020); cost of electricity was based on a generic kWh estimate of 0.12 per kWh. The flow rates were a low, medium and high selected based on all the observed data for the trial period. This was then used to calculate the average cost for BOD removal for both a variable speed pump and a fixed speed pump, a summary is shown in Table 1; for brevity, the overall cost average for the entire trial period is shown.

Table 1 – Estimated Cost Saving with BOD removal using Proteus.

Over 12 months, based purely on BOD, the savings are considerable. This data will vary between each treatment works depending on individual machinery specifications and treatment procedure, but the savings margins are by no means small to start with. There is considerable scope for increased cost and operational efficiency for the most expensive and energy-intensive part of the wastewater treatment process.

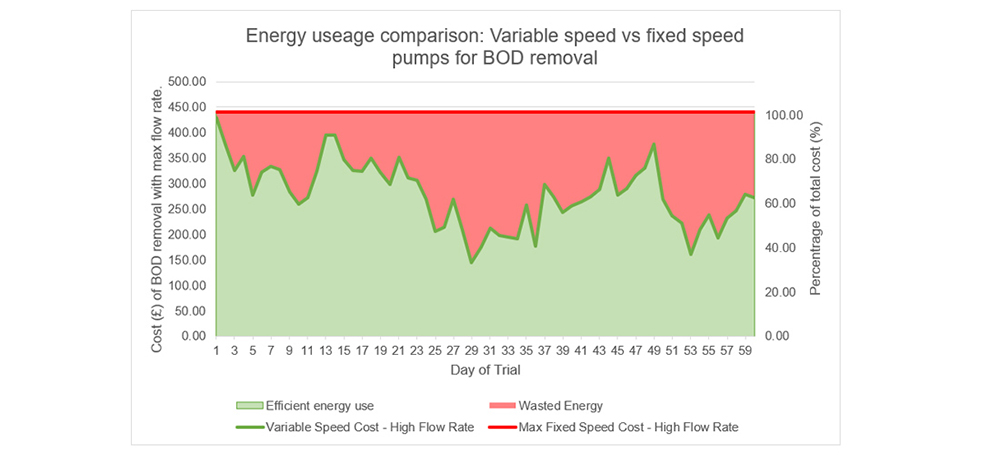

Figure 4 – A graph showing the difference in cost between the use of a fixed-speed aeration pump and a variable-speed aeration pump based on observed BOD values and a high average flow rate Feb-April 2018. Shaded areas show the potential cost of energy used and lost between the variable and fixed speed pumps

Permit ranges are also important to consider when optimising wastewater treatment. Operation within permit limits is essential but imprecise data can prevent the permit being utilised fully. Essentially, when data is not specific enough, such as using DO to program the blowers, it reduces efficiency and causes leaks in energy and spending. BOD is far superior to DO when considering feedback and feedforward control as DO only monitors the oxygen level without accounting for the balancing of the bacterial biomass.

The sheer difference in value between the variable and fixed speed pump costs clearly demonstrates the enormous potential for real-time BOD monitoring to optimise wastewater treatment and transform the efficiency of individual processes. Even on a daily basis, there is substantial room for increasing efficiency and lowering of the operational costs. While the figures quoted are based on very specific, high-resolution data, the scope of what could be achieved by monitoring BOD is clear. It is unlikely that there is any site that could not improve efficiency and reduce costs by monitoring BOD or COD in real-time. The discussion of cost has mainly been focused on running costs, but there are also massive implications for reducing unnecessary wear and tear on machinery, thereby reducing service costs and increasing service life.

Real-time BOD can be used to improve upon existing control parameters like ammonia and DO. The potential to utilise permits more fully while maintaining compliance regulation is a game-changer for further increasing efficiency and optimisation of the wastewater treatment process. Real-time BOD monitoring can offer a level of control that has previously been unattainable, and it can completely change the way we consider wastewater treatment. Going forward, fluorescence technology is setting a new standard for wastewater treatment monitoring, allowing far greater control, and understanding of the process as a whole than has been previously achievable.

Read more Proteus Instruments Articles and News on H2O Global News. Do you have an article or video that you would like to share? Submit your article here or keep up with the latest news from the water industry and wastewater industry by subscribing to our weekly newsletter