DReeM Polymer™

Description

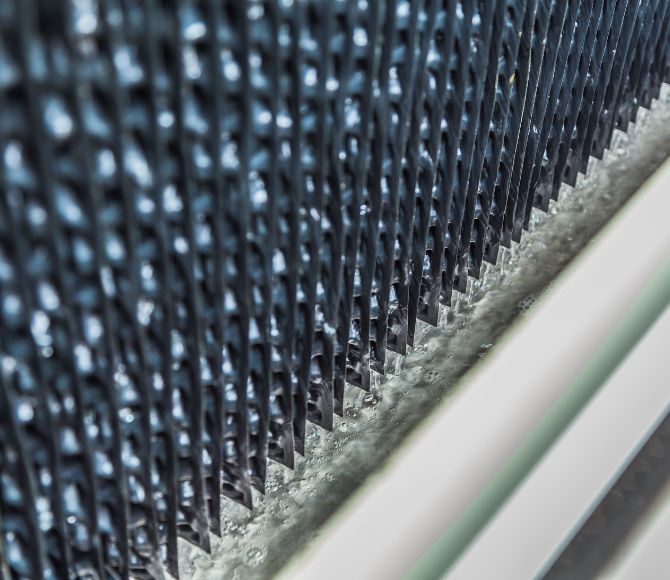

Kurita’s award-winning DReeM Polymer Technology has the ability to remove silicate and hardness scale from boiler surfaces up to four times more efficiently than conventional polymers. This unique chemistry was developed to maximize heat transfer surface cleanliness and efficiency and minimize fuel costs in low- to medium-pressure boilers. It is unparalleled as an on-line cleaner of silicate and iron silicate boiler deposits. It is also highly effective at dispersing silicate compounds and preventing calcium hardness deposition.

Not only do boiler treatment blends using DReeM Polymer maximize efficiency on boilers with well-maintained pretreatment equipment, they also provide outstanding heat transfer surface cleanliness for systems with occasional pretreatment system upsets as well as on-line cleaning of systems recovering from hardness upsets. DReeM Polymer has the effectiveness of EDTA chelants without the corrosion concerns and meets the requirements of 21 CFR 173.310, which means it is intended for use in food plants.

Company Description: Kurita offers innovative water treatment solutions via technologies, engineering, and services. Our global, customer-focused teams get to the root cause of your facility’s most complex water challenges to deliver optimal results while conserving natural resources.