Owned and operated by Yuba Water Agency, New Bullards Bar Dam is a 645-foot-tall concrete arch dam, making it California’s second tallest dam and the fifth tallest in the United States. It is situated in the Yuba County foothills on the edge of Tahoe National Forest with a capacity to hold 1.19 cubic kilometers of water, forming the New Bullards Bar Dam Reservoir that provides flood control and serves as a popular recreation area. Built in 1970, the dam helps to reduce flood risk, generate clean hydropower, and ensure reliable water supply for county residents, the area’s rich agricultural community, and the environment.

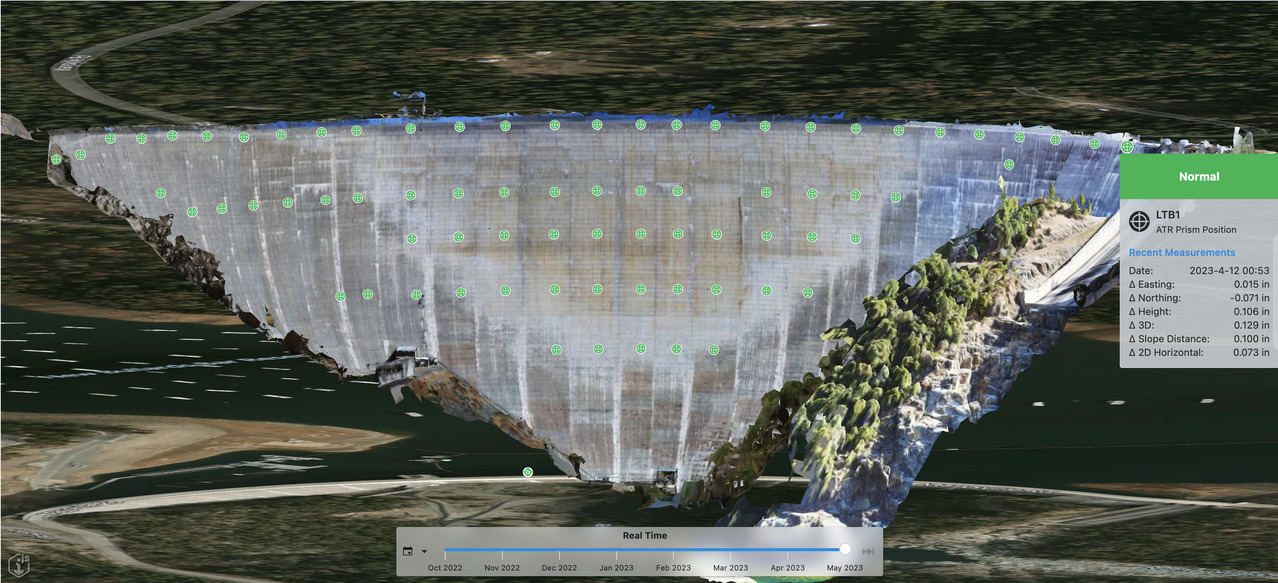

Committed to dam safety and improving operational efficiencies and reliability, Yuba Water initiated a project to modernize the dam’s legacy monitoring system, implementing real-time data collection, digital visualization, and automated monitoring. “The project was implemented so Yuba Water can better understand the entire performance of New Bullards Bar Dam, especially when dealing with inclement weather and seismic events,” said Tim Truong, chief dam safety engineer at Yuba Water. With multiple monitoring prisms and pylons, the smart digitized system provides real-time insight into movement of the dam structure over time as it is exposed to different natural elements, accelerating detection of dam deformation and improving risk assessment and dam safety.

Safety Hazards, Site Constraints, and Security

“The project involved performing drone surveys and installing automated survey instruments that provide a comprehensive set of capabilities for detecting cracks and 3D deflection of the structure, along with monitoring any propagation,” said Truong. To implement the digital monitoring system, the project team had to establish local survey benchmarks and install reflective target sensors across the dam face, as well as construct a secure enclosure to house and protect the automated motorized total station. This situation presented challenges when obtaining permits and approvals for drilling and installing the devices. The team also faced challenges with the engineering and construction activities necessary to build the dedicated security enclosure for the survey equipment at a remote location while ensuring visibility of the entire downstream dam face. Compounding these issues was the steep terrain around the dam, accessible only via a narrow, restricted road.

The dam’s previous monitoring system relied on manual, time-consuming data collection that spanned only a portion of the dam at any given time. It also posed fall hazards to the survey team amid the remote terrain. Yuba Water sought to implement a cost-efficient and comprehensive smart monitoring system, enabling holistic insight into dam movement and conditions. To develop their intelligent monitoring solution, they needed integrated reality modeling and digital twin applications facilitating remote, real-time data collection and visualization with automated alerts of potential issues, while securing the on-site digital survey station equipment.

Leveraging iTwin Provides Comprehensive Monitoring Solution

Yuba Water used iTwin IoT to establish a digital twin of the entire dam. The digital twin now enables the team to visualize the sensor data and monitor movement and behavior of the dam structure over time as it is exposed to different elements and perform real-time risk assessments. “Using iTwin IoT, the dam can be monitored more closely during heavy rainfall and be checked on quickly if earthquakes or other major weather events occur,” said Truong.

Bentley’s digital twin applications provide automated decision support thorough dashboards and reporting on structural integrity and reliability of the dam. “Bentley software was chosen because of its ability to collect monitoring data remotely and automate analysis and alerts based on predetermined thresholds,” said Truong. The team can now track the direction of deformation directly on the digital twin without having to utilize multiple software platforms. Working in the iTwin Platform, Yuba Water can track events, provide timely alerts, and report to stakeholders all in one platform, while having peace of mind that the secure system locks access to the total station for most of the time that live monitoring is not occurring.

Digital Twin Drives Situational Intelligence for Optimal Risk Assessment

“Going digital has allowed us to communicate the needs of the project effectively with the members of our team and visualize the data in real time,” said Truong. The original approach to the dam monitoring would take about one week to get a data point from a target and cost USD 5,000 for each manual data collection event. The new cloud-based system collects a data point from over 80 prisms twice a day and makes it immediately accessible to all authorized users at no extra cost other than the purchase of the iTwin software.

Compared to conventional monitoring, the digital twin fully provides insight into how the dam performs in the real world with greater accuracy over time, optimizing risk assessment and driving situational intelligence, paramount to achieving the agency’s goal of ensuring public safety and protecting the environment. “For Yuba Water Agency, there is nothing more important than public safety. Investing in a real-time, automated total monitoring station at New Bullards Bar Dam significantly improves our monitoring capabilities and is testament to our continued commitment to public safety and infrastructure resilience,” said Truong.