Hydrogen peroxide is a very useful chemical – the extra oxygen atom makes it a powerful oxidant, which is used in a variety of industries, from agriculture to industrial and municipal water treatment.

Unfortunately, the present-day hydrogen peroxide supply chain is far from sustainable. Today’s hydrogen peroxide plants are centralized, costly, and emit high levels of greenhouse gas emissions. Hydrogen peroxide is shipped from these centralized plants to millions of end users, requiring specialized transportation, handling and storage. Also, many hydrogen peroxide plants use natural gas as a raw material, which leads to additional sustainability and supply chain challenges.

CO2 emissions

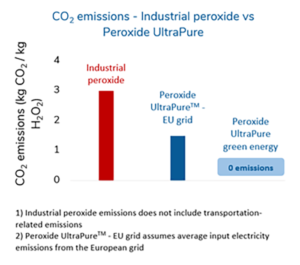

The traditional hydrogen peroxide supply chain generates high CO2 emissions due to the use of hydrogen as a raw material as well as the energy requirements of the chemical process. On average, for each kg of hydrogen peroxide generated through the industrial process, 3 kg of CO2-equivalent emissions are released into the atmosphere. On top of this, hydrogen peroxide is produced at centralized chemical plants and needs to be transported to end users, which results in additional emissions.

Natural gas consumption

With access to natural gas becoming more limited, another issue of concern is the consumption of that increasingly scarce resource by the traditional hydrogen peroxide supply chain.

Hydrogen peroxide produced industrially requires hydrogen. In many cases hydrogen is produced from natural gas, and it takes about the equivalence of 260 liters of natural gas to produce 1 kg of H2O2.[1] Other sources of hydrogen include coal and oil. With the current instability on natural gas availability and pricing, this is straining supply of hydrogen peroxide, and it is a key factor in the price fluctuations the market is experiencing.

Sustainable alternative – make your own peroxide, on-site

Fortunately, a sustainable alternative to produce hydrogen peroxide is available that uses electricity and does not require hydrogen – or natural gas: The HPGen is a hydrogen peroxide generator that produces hydrogen peroxide on site, with only electricity, water and air as inputs.

HPGen is fully independent from external raw materials, and enables production of hydrogen peroxide directly at the point of use. In that way supply of hydrogen peroxide can be secured and users are protected from price fluctuations. In addition, thanks to a highly energy-efficient production process, the operational carbon footprint of HPGen is lower than for industrial peroxide.

For example, when considering the European grid average, CO2 emissions are less than half. When renewable electricity is used, the operational carbon footprint is exactly zero. This occurs in several HPGen installations where solar panels are used to provide electricity in a fully off-the-grid implementation.

Vítor Gomes, owner and director of a company providing agriculture supplies in Portugal, comments: ‘HPGen produces top quality hydrogen peroxide for irrigation water treatment. By manufacturing their own peroxide, our clients have the peace of mind that price will not increase, and they do not need to worry about availability or delays in supply. In addition, the process can be CO2 free when powered from solar farms, which is a big boost for our sustainability efforts.’

Because the peroxide is generated directly on site, no specialized transportation, handling and storage is required either, making the HPGen solution an interesting alternative to the volatile hydrogen peroxide supply chain.

[1] Not all hydrogen used for hydrogen peroxide production comes from natural gas; it largely depends on the geography.

Read more HPNow Articles and News on H2O Global News. Do you have an article or video that you would like to share? Submit your article here or keep up with the latest news from the water industry and wastewater industry by subscribing to our weekly newsletter