Location: Hurghada, Egypt

End User: Hilton Hurghada Plaza

Plant Capacity: 1,000 m3/day

The Challenge

Provide Reliable, Clean Water at a Low Cost

Resorts and hotels by the Red Sea in Egypt depend on seawater desalination to provide a reliable and energy-efficient source of clean, potable water. In 2019, a seawater reverse osmosis (SWRO) plant was commissioned for the Hilton Hurghada Plaza in Hurghada, Egypt, designed to provide 1,000 m3/day of clean water to hotel guests. The desalination facility helps supplement the region’s freshwater supply and eliminates the need to tap into local water sources.

Desalination plants rely on energy recovery devices (ERDs) to lower energy consumption and make the process cost-effective. The plant originally chose to test and install an alternative ERD, but subsequently reported operational issues related to stalling and high vibrational sound levels. After a few months in operation, the customer decided to replace their existing rotary isobaric ERD to avoid downtime and ensure the hotel was able to provide the essential potable water guests needed.

The Solution

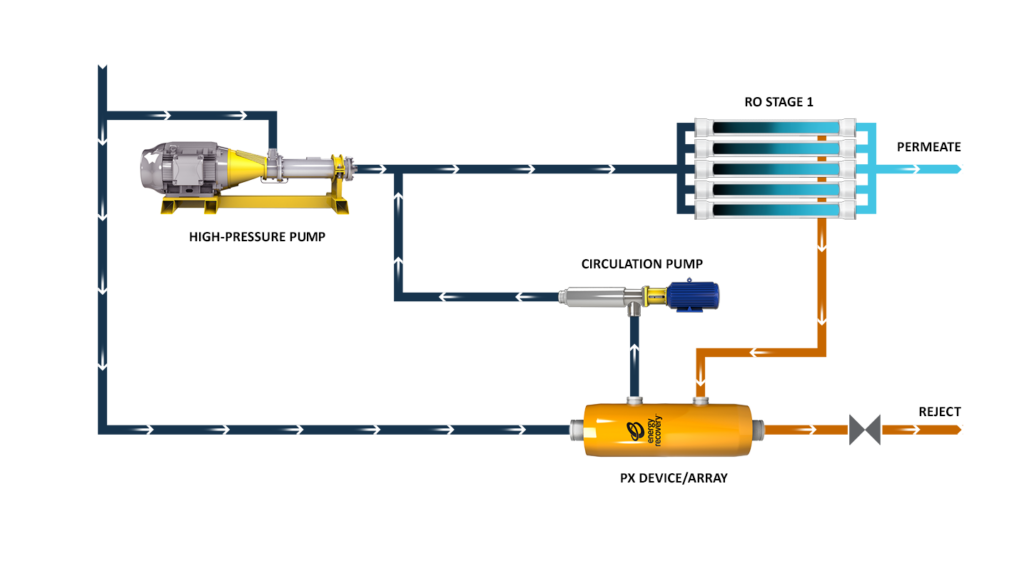

Retrofit with the PX Q300

Resolving the issues meant replacing the initial energy recovery device with one that was well-known and tested for success. The EPC contractor decided to utilize a proven solution they already had on hand, Energy Recovery’s PX Q300, to ensure seamless integration and plant uptime. The PX Q300 is a highly efficient PX® Pressure Exchanger® from the PX Q series line, an optimal choice due to its 45.4 – 68.1 m3/h f low rate suited for the desalination facility’s design. The EPC contractor ultimately pivoted to the PX because of Energy Recovery’s proven track record for reliability and dedication to energy efficiency technology with over 30,000 PXs deployed globally and a 30-year design life.

The Hilton Plaza chose Energy Recovery’s product solutions for three critical factors:

- Premier Quality: Having rigorous quality control and a proprietary in-house manufacturing process, Energy Recovery tests devices to the highest standard.

- Superior Customer Support: The PX Q300 was successfully commissioned with a short lead time and prompt customer support. With the previous ERD, the end user reported trouble getting service support and obtaining replacement and spare parts.

- Trusted Reliability: Energy Recovery’s PX® Pressure Exchanger® is trusted and proven. With over 30,000 devices deployed worldwide, many of which are installed in mega desalination plants (>100K CMD), the PX delivers quality performance, a 25-year design life, and no scheduled maintenance.

“As the proud sponsors of the Hilton Hurghada Plaza Desalination Plant in Hurghada, Egypt, supplying 1,000 m3/d of fresh water, we are delighted with our choice of Energy Recovery’s PX Q300 as our energy recovery solution. …the PX Q300 maintains the plant availability and eliminated the downtime. We enthusiastically recommend Energy Recovery’s PX Q300 as the most reliable and affordable solution for energy recovery on the market today.” -Hilton Hurghada Plaza

The Result

A Trusted Solution for Continued Uptime

After replacing the previous ERD with Energy Recovery’s PX Q300 in 2019, the plant has successfully produced 1,000 m3/day of freshwater for resort guests. The PX Q300 has continued to perform above expectations, ensuring plant availability, and reducing the system’s energy consumption. The Hilton Hurghada Plaza efficiently provides clean water with the help of the PX, chosen due to its proven quality, associated service and support, and reliability.