Exclusive: H2O Global News’ Natasha Posnett spoke with Duperon President, Mark Turpin, and Mechanical Engineers, Bryce Funchion and Steve Dill, about their new technologies and how they are addressing resilience in wastewater treatment.

The world of wastewater is changing faster than ever before. New pressures have arisen which require adaptation and innovation throughout the industry. Population numbers are still on the rise, ageing infrastructure is becoming more common and extreme weather events are increasing in frequency and intensity- all of which impact the efficiency of wastewater treatment.

Screening is a key component of wastewater treatment; it works to separate solids from liquids and without it, huge amounts of damage would be inflicted on process equipment and clogs would be numerous. But with all of the changing conditions that treatment plants are faced with, it is difficult to make screening successful and efficient. Engineers have been left with the challenging job of designing screening technologies that work for everyday conditions while still meeting the demands of peak flows and unexpected events.

Duperon is a company which specialises in preliminary solid and liquid separation and it has recently invented two new technologies with the issue of resilience in mind. Their adaptive designs are allowing them to treat wastewater more efficiently and with greater resilience. They are able to meet the demands of an ever changing environment and keep the water flowing under all circumstances.

Duperon President, Mark Turpin said: “The need for plants to build resiliency into their design for wastewater is an emerging topic in the water industry. Some plants are seeing that their peak flows are five to 10 times higher than their average flows! The engineers have the tough job of needing to account for that in their designs.”

DAS in application

New technologies providing new levels of adaptability

FlexRake IQ and IQ2

The FlekRake IQ series is an progression of Duperon’s original 1990’s screening technology. It offers an adaptable bar screening solution for wastewater treatment plants. The new FlexRake IQ and IQ2 have the same simplicity and reliability as the original design, but have been adapted for today’s challenging plant conditions. The new design increases debris removal and the capacity to accommodate changing circumstances. During peak flow events, the optional FlexRake IQ2 physically adjusts the screen itself to provide maximum flexibility.

Duperon Mechanical Engineer, Bryce Funchion said: “We have had the original FlexRake line for over 25 years. During this time we gained a lot of experience and background knowledge, we applied this experience in the FlexRake IQ design with responsive raking and smart bar screen features that address today’s challenging debris and hydraulic conditions.”

Today’s conditions have challenged civil engineers when sizing the screen for a community’s everyday conditions without causing backups during peak events. The design of the FlexRake IQ and IQ2 solves this problem.

Funchion explained: “We understood that treatment plant operators require real-time responsiveness to deal with changing conditions in the channel. We looked at the problem and wondered ‘what if the engineer didn’t have to modify their design to accommodate changing conditions? What if the screen itself adapted to them?’ We created the new design to provide an increased safety factor which assures system reliability during both normal flows and worst-case scenario events and everything in-between.”

The Smart Bar Screen – physically transforms the screen field to allow additional hydraulic throughput

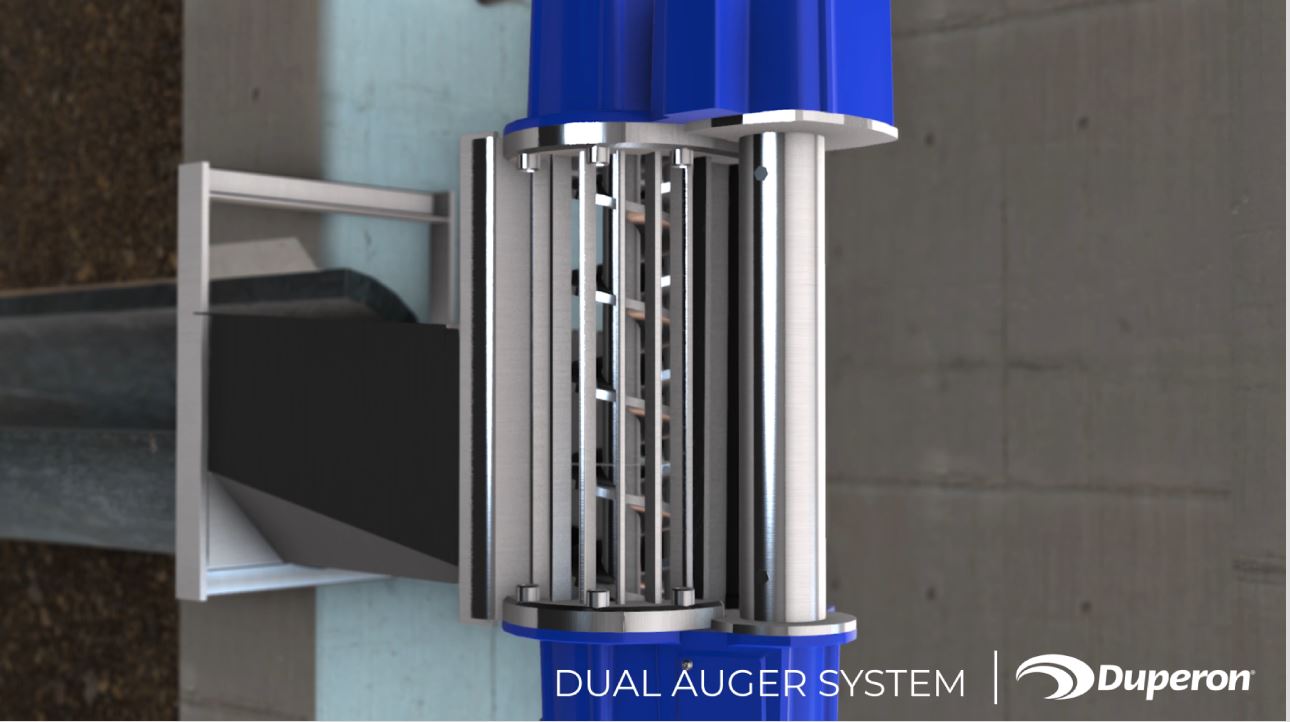

Dual Auger System

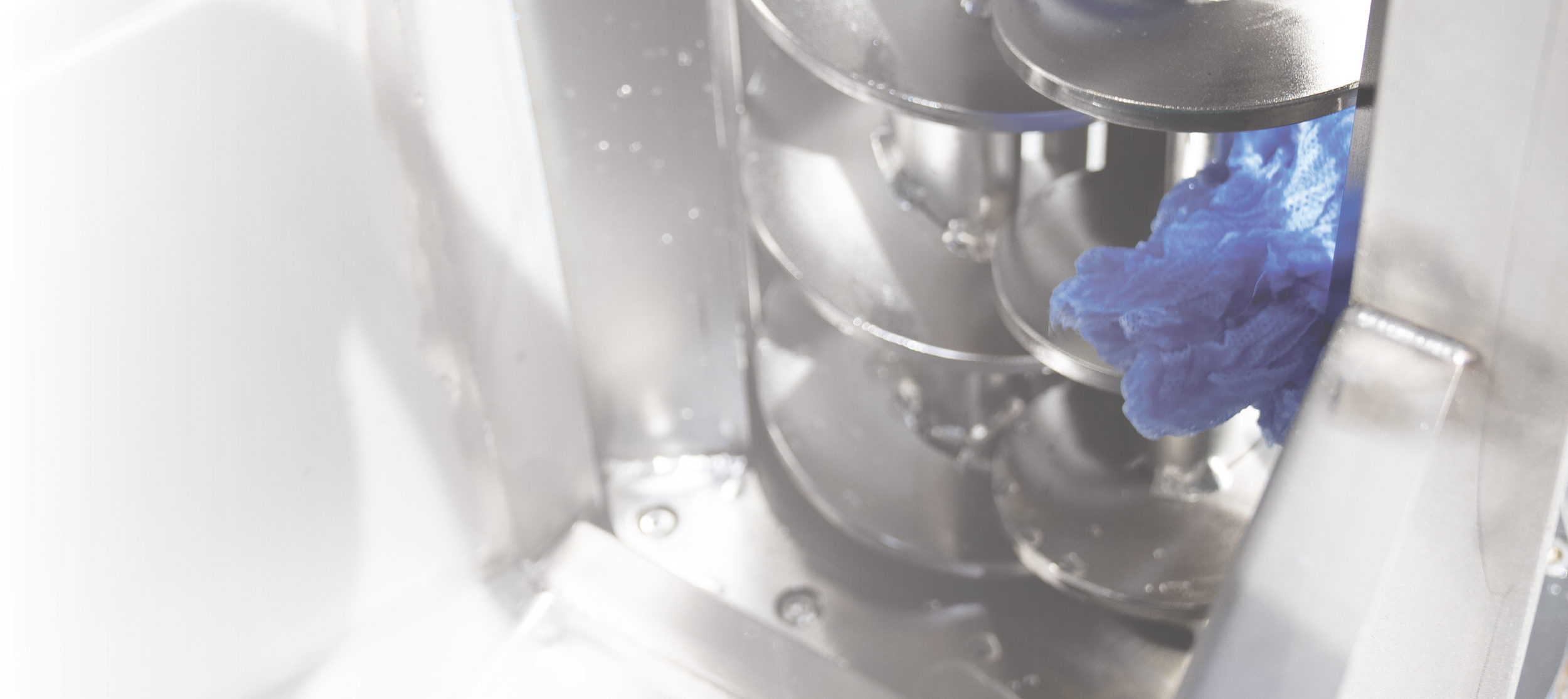

The Dual Auger System (DAS) is a solution to pump clogging. It works to remove flushable wipes and other debris at or near the point of entrance in the collection system, before downstream equipment can be damaged.

Duperon Mechanical Engineer, Steve Dill said: “Current solutions require significant labour and do not alleviate the problem. Most systems either require manual, emergency pump cleanouts or grind wipes into smaller pieces that re-constitute downstream.”

Systemwide resiliency is restored by removing non-dissolvable solids at their source point in the collection system. This allows the sewer network to operate as it was designed, unimpeded by wipes. It also allows the wastewater treatment plant and processes to have more operation reliability and less maintenance from the carryover of problematic debris.

The DAS offers a mechanical solution that dramatically reduces hands-on labour. It captures, dewaters, compacts and conveys solids in a single system; replacing emergency maintenance with simple and infrequent solids pick-ups and eliminating sewer backups.

The shift towards resilience

Resilience is an evolving theme in the water sector. For both now and for the future, it is an area essential to focus on because the world requires a reliable source of water that can adapt and respond to change. Global threats will continue to pose challenges for the water sector over the coming decades; implementing resilience is the answer people are looking for. However, a deeper understanding of resilience and how it can be successfully applied at an operational level are crucial if the industry is to manage and respond to changing conditions.

The wastewater environment is always going to be subject to change and that is where Duperon’s adaptive technology works the best, allowing the needs of the plan to be met.

A story of success

Duperon’s new technologies are working to ensure resilience in the wastewater process and reflect what it means to be resilient. They are keeping water flowing optimally even under harsh conditions. It is still early days for their new technology, but it is great to hear that it is being accepted in the industry with positive feedback and results.

Turpin summed up: “Already, a very large percentage of our overall projects have shifted to these new products. The engineering community has accepted these solutions readily and it is all progressing quickly. We are very happy with the early feedback we are getting and we are excited to learn more.”

This does not mean that the hard work is over for Duperon. It is a continual process of making improvements and aiming to get the best results possible for people and the environment.

Turpin explained: ”Part of the way we develop products is to be with the customers. We like to see how the instillation is working, learn from the operators and their experience and then continue to perfect and move forward our designs depending on the unique needs of our clients.”

Duperon values the work that is being done every day at wastewater treatment plants around the world and that is reflected in their work. The water industry has many hurdles to overcome in the coming years, but it is made easier when companies work with peoples best interests at heart.

Turpin made a great point: “The operators at wastewater treatment plants are heroes who go to work every day to solve a problem for society that no one really wants to think about. They are protecting clean waterways and giving us clean drinking water sources, so anything that we can do at Duperon to make their life easier and make them more successful in that mission, is well worth doing.”

Do you have an article to share? Click here to submit or if you’d like to subscribe to our weekly newsletter, click here.