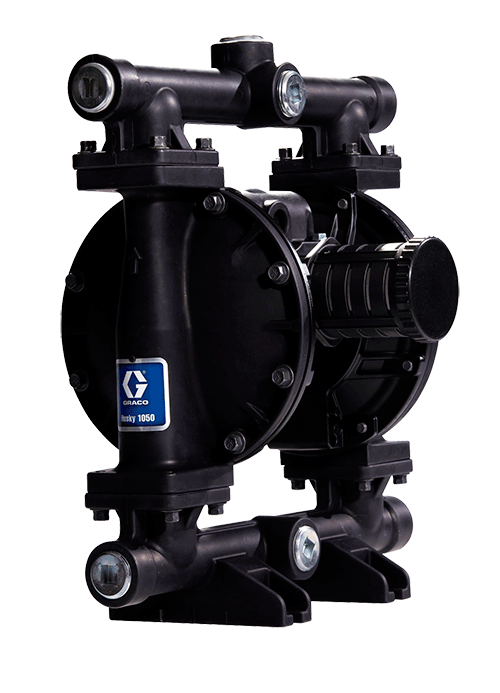

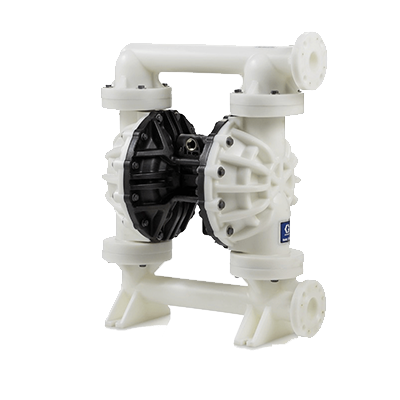

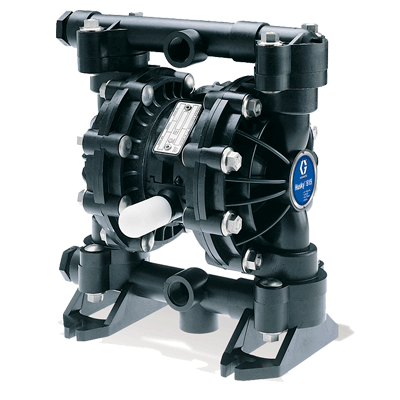

Diaphragm Pump

Description

A Diaphragm Pump is a robust and versatile solution designed to handle a diverse range of fluid handling applications. A Diaphragm Pump is designed to deliver exceptional performance, reliability, and efficiency.

The key features and benefits are versatility in how it handles fluids, the compatibility with a number of different chemicals, and the ability to be a positive displacement mechanism.

Versatility in Handling Fluids

The diaphragm pump stands out for its ability to manage liquids of varying viscosities and those containing suspended solids. This makes it ideal for a diverse array of applications, from transferring thick, sludgy substances to pumping clear, light fluids. Whether you are dealing with water, oil, chemicals, or slurries, this pump handles them all with ease.

Chemical Compatibility

Constructed from high-quality materials such as rubber, thermoplastic, and PTFE (Teflon), the diaphragm pump is engineered to withstand the harshest environments. Its chemical-resistant properties ensure that it can handle aggressive and corrosive chemicals safely and efficiently. This makes it a preferred choice in industries such as chemical processing, pharmaceuticals, and food and beverage production.

Positive Displacement Mechanism

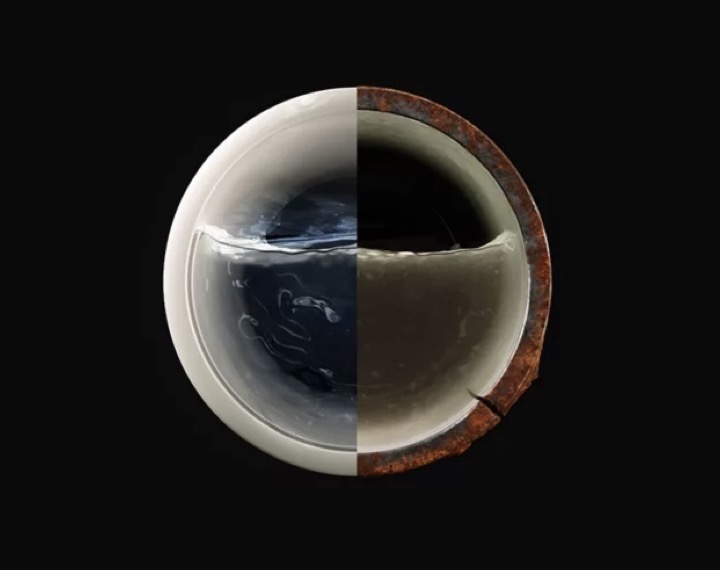

At the heart of the diaphragm pump is its positive displacement mechanism. This involves a diaphragm that reciprocates within the pump, creating a change in volume that moves the fluid. The diaphragm's movement is controlled by compressed air, which is directed back and forth between the two sides of the pump by a pneumatic valve. This results in a smooth, continuous flow of liquid, free from pulsations and disruptions.

There are 3 main types of Diaphragm Pumps

Those three types of diaphragm pumps are single diaphragm, electro-mechanical, and double diaphragm.

1. Single Diaphragm Pumps: These pumps are sealed on one side with the fluid to be pumped, while the other side contains air or hydraulic fluid. The diaphragm flexes to change the volume of the pump chamber, and non-return check valves ensure one-way fluid flow.

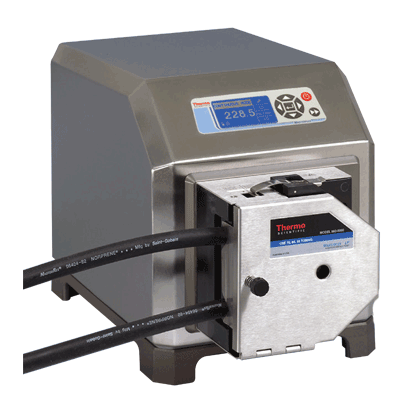

2. Electro-Mechanical Diaphragm Pumps: These use an electro-mechanical prime mover, such as a crank or geared motor, to drive the diaphragm. This setup is ideal for applications requiring precise control and consistent performance, with one side of the diaphragm exposed to air.

3. Double Diaphragm Pumps: In these pumps, the diaphragm flexes with fluid on both sides, creating a reliable pumping action. This configuration is particularly effective in applications requiring robust performance and high durability.

Diaphragm Pumps can be used in a wide variety of industries including chemical processing, water treatment, pharmaceuticals, food & beverage, mining, and construction.

A Diaphragm Pump is a wise choice for businesses seeking reliable, efficient, and versatile fluid handling solutions. Its ability to manage a wide range of fluids, coupled with its robust construction and positive displacement mechanism, make it an indispensable tool in many industrial settings.