Did you know that the UK loses billions of liters of water every single day due to hidden leaks? What’s surprising is that the advanced technology meant to improve water infrastructure is making leaks harder to detect. Upgrading old, rusty pipes with modern, durable materials sounds like a great idea until you realize these new pipes can hide leaks for years, wasting precious water without anyone noticing.

So, how can we solve this? The answer lies in combining smart solutions like acoustic sensors, thermal imaging, and satellite technology with modern strategies. In this article, we’ll break down why leaks are getting trickier, how upgrading critical infrastructure is necessary to meet modern needs, leak detection, and water leak solutions.

Modern Water Infrastructure: A Hidden Problem with Leak Detection

The UK has historically struggled with aging and leaking water infrastructure. In recent years, companies have made major investments using innovative technologies to upgrade pipes across the country. However, these advanced plastics and metal alloys have made leaks more difficult to detect.

Many water companies have replaced old iron and steel pipes with durable plastic like polyethylene or tough metal alloys. While these materials are designed to last up to 100 years, their non-corrosive and seamless nature means leaks are hard to spot with traditional methods. As pipes have been upgraded, the number of reported leaks has dropped, but real losses are suspected to remain high due to undetected seepages.

To address this issue, water companies have invested in acoustic sensors that listen for the sounds of leaks, satellite imagery to detect ground movement, and tracer gases for pinpointing pipe failures. Still, leak detection remains an ongoing challenge, with thousands of miles of underground pipes spread across vast geographies.

Consumers and regulators argue that companies should do more to curb water losses, especially given the high costs of service. However, water companies counter that leak detection has become increasingly difficult as technology has improved infrastructure. They note significant investments in advanced metering, pressure management, and leak reduction programs, all while keeping consumer rates affordable in an essential public service.

Incorporating cutting-edge technologies is crucial for transforming outdated water systems. Innovative solutions are helping the industry adapt to modern challenges and secure future resources. Discover the latest advancements in water technology.

Nature of Water Leaks In the UK

The UK’s ancient water infrastructure, much of which stems from the nineteenth and early twentieth centuries, is prone to water pipe leaks. Factors that contribute to leakage include:

- Corrosion in older pipes.

- Pressure surges in water systems.

- Cracks are generated by ground movement or freezing temperatures.

The amount of water lost is staggering: approximately 3 billion gallons per day in England and Wales alone. Addressing these leaking water lines is critical for conserving water and reducing costs. Explore more about sustainable water management practices.

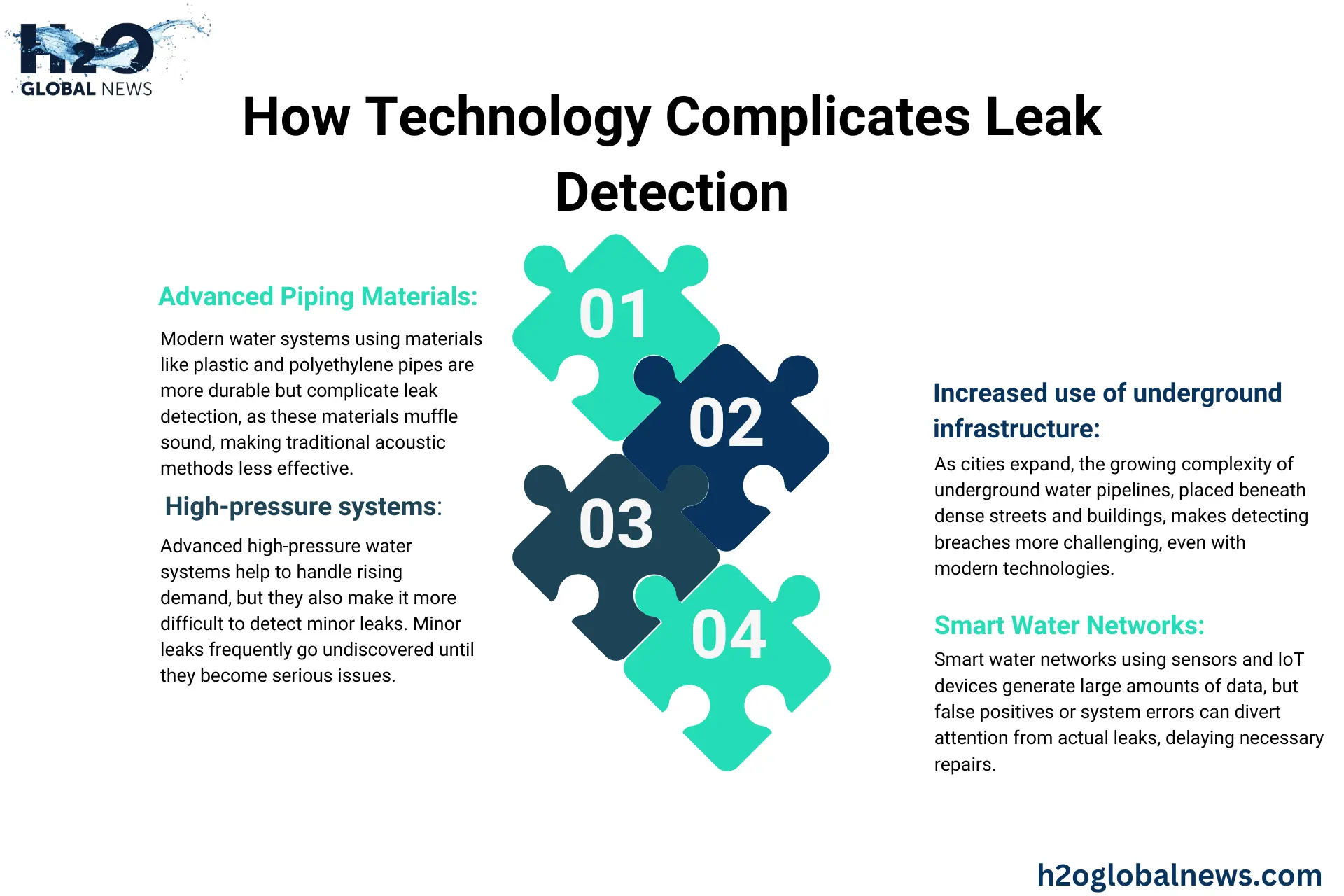

How Technology Complicates Leak Detection

Despite its benefits, advanced technology has made it harder to identify hidden water leaks in modern infrastructure:

Advanced Piping Materials

Modern water systems frequently use materials like plastic and polyethylene pipes, which are more resilient than old metal pipes but pose detecting issues. These materials muffle the sound of leakage, making acoustic detection ineffective.

Increased use of underground infrastructure

As cities grow in size, more water pipelines are being placed beneath densely packed streets and buildings. This increased complexity makes it more difficult to detect underground water pipe breaches, even with modern technologies.

High-pressure systems

Advanced high-pressure water systems help to handle rising demand, but they also make it more difficult to detect minor leaks. Minor leaks frequently go undiscovered until they become serious issues.

Smart Water Networks

Smart water networks, which utilize sensors and IoT devices to monitor flow and pressure, can generate massive volumes of data. False positives or system mistakes can deflect attention away from true water leaks, delaying necessary action.

Effective Water Leakage Solutions

Water leaks must be addressed by a combination of technology, infrastructure enhancements, and increased public awareness. Key water leak solutions include the following:

- Regular Maintenance: Scheduled inspections using modern instruments lessen the likelihood of undetected leaks.

- Public Reporting: Encouraging communities to report obvious leaks can supplement technology-driven initiatives.

- Investment in Smart Infrastructure: Utilities should extend smart water networks and implement technology such as AI and digital twins.

- Professionals who work with modern leak-detecting systems require up-to-date training.

Ensuring water quality and reducing waste requires not just leak detection but also improved treatment processes. Explore advanced water treatment technologies that are revolutionizing water management.

Conclusion

Technology may have made detecting water leaks harder, but it also holds the key to solving the problem. The UK can efficiently solve water pipe leaks by combining sophisticated leak detection technology, preventive maintenance, and infrastructure investment. Collaboration among governments, utilities, and residents is critical to saving water resources and ensuring a sustainable water future. By working together, the United Kingdom may transform its water leak problem into an opportunity for wiser, more effective water management.

FAQs

1- How can individuals detect leaks at home?

Homeowners can check for unusually high water bills, wet spots, or dripping sounds. Smart water meters can also alert them to potential leaks.

2- What is Acoustic Sensing?

Acoustic sensing uses sensitive microphones to listen to the sounds of running or dripping water in pipes. The microphones are placed on fire hydrants, water meters, and main supply lines. Any noises indicating a leak are detected, pinpointing the location and severity. Acoustic sensors can identify leaks early, even small ones that release as little as 0.2 gallons per minute.

3- What is water seepage vs leakage?

Seepage is when water slowly escapes through tiny pores or cracks in materials like soil or concrete. It’s usually a gradual process. While, Leakage is water escaping through visible cracks, holes, or gaps in pipes or systems. It’s more noticeable and often more serious.

4- Which chemical is best for water leakage?

For concrete or walls, polyurethane foam or epoxy works best to seal cracks. Silicone-based sealants are great for plumbing pipes, while bitumen waterproofing is ideal for roofs.