The water industry has always had to deal with the challenge of proper asset management and has used different policies and practices to maintain and renew them over the years. In recent years, leading water utilities have been building intelligent asset management into their processes. As a result of the deployment of sensors on their infrastructure and the implementation of other technologies such as micro-metering, GIS and SCADAs, utilities have an ever-increasing volume of information available on their assets. In this context, intelligent management integrates and organizes all this data in order to make better decisions. It advances on the conventional approach, which is characterized by corrective maintenance.

Today, the water industry is adding intelligent management with the ultimate goal of maximizing efficiency. Although utilities have varying degrees of digital maturity, there is a definite trend towards moving in this direction.

Based on experience, the application of technology paves the way for different use cases. For example, the history of work orders carried out on an asset can help assess the risk of failure and determine when it should be replaced. Thus, utilities can extend the lifetime of assets, anticipate replacements, adjust maintenance tasks and prevent outages. In addition, these systems help to pinpoint the most problematic materials, making real preventive maintenance possible and even guiding future investments. In addition, the management of pumps and other operating elements can optimize their energy consumption and provide better service.

In short, more efficient resource management brings significant economic and environmental benefits by reducing costs and energy consumption. It also optimizes productivity, ensures service availability and reduces downtimes.

Rafael Rubio, Head of IT Operations at Idrica, forecasts the trends in intelligent asset management for 2022.

Management inputs

There are a number of essential inputs required for sound asset management. First of all, operators must have a comprehensive list of the master data involved in the production process. This inventory includes the characteristics associated with each asset: economic (acquisition and replacement cost, cumulative depreciation, etc.), technical (inherent to each type of device, such as power) and operational (theoretical operating conditions, tolerances, estimated availability, curves, etc.). The relationships between assets, such as topological connections and asset hierarchies, must also be recorded.

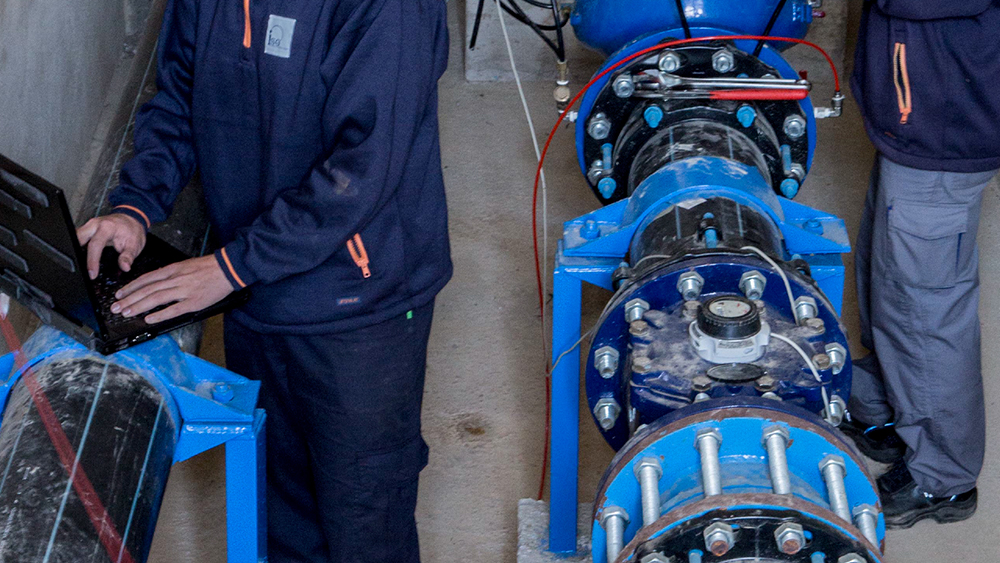

Transactional data are another key input. They contain different types of data, for example, that are obtained from micro-metering and sensor technology, which are closely related to the Internet of Things (IoT). They also include information on incidents, such as their cost, downtimes and idle times, by their cause and origin. This group of elements also includes consumption estimates, generated by a mathematical model based on predicted or simulated conditions, together with a log of the work conducted on the assets in a CMMS system.

This information is used by Artificial Intelligence (AI) and Machine Learning (ML) based algorithmic modules to suggest the most appropriate actions to be taken. The circle closes as the results of these actions become a new input for the system, feeding the AI and ML engines.

Smart CMMS: taking maintenance to the next level

Automated Computerized Maintenance Management Systems (CMMS) are the best example of the application of technology to management and maintenance when combined with intelligent management. They have already become an essential tool in the introduction of best practices and are valuable in addressing resource scarcity. In addition, they help utilities to obtain certifications related to new environmental and organizational standards, such as ISO 5500.

There are numerous benefits to implementing these systems, thus guaranteeing ROI. The investment implies improved safety for facility and equipment users. It also enhances product quality, reducing costs and giving the utility a competitive advantage. By increasing production capacity and decreasing the probability of failures in systems and facilities, service availability is boosted and, by extension, the satisfaction of internal and end users increases.

In addition, utilities can optimize their administration processes by directly managing work orders using a mobile tool and drawing on the administrative support provided by the CMMS. This streamlines the management, organization and planning of maintenance work. In terms of costs, the reduction in the use of spare parts and the increased productivity of the facilities free up working hours and cuts down idle times. Thus, cash flow improves, and profitability rises.

Moreover, the optimization of preventive maintenance on facility elements usually reduces the energy used by mechanical equipment by 5% to 10%. Ensuring they are in good working order and monitoring their consumption enables proactive, automatic action to be taken in the event of any deviations. This is particularly important in a context marked by global warming since improvements in energy efficiency help to mitigate the impact of the activities that need to be carried out.

A key part of CMMS is the automation of supply procurement in the warehouse. This enables the system to place the necessary orders to ensure facility maintenance, according to previously established minimum indicators. This reduces downtimes when replacing parts as stock is available.

Finally, it is important to highlight how the mobility tool included in these systems increases maintenance management efficiency. The geolocation of fleets, together with the optimization of maintenance routes, leads to a reduction in travel time and distances, leading to a smaller carbon footprint and reducing related costs.

In general, these tools increase productivity, reduce administration time, and collect field data in digital format. They also serve to train new technical staff by providing them with different procedures, manuals, videos and photographs of work orders that have already been completed.

Roadmap for 2022

Over the next few years, intelligent asset management is set to grow dramatically in the water industry. In a world that is increasingly concerned about environmental sustainability, the larger amounts of data available, provided by infrastructure sensors, will enable companies to progress towards more efficient resource management.

One of the main challenges lies in overcoming the technological complexity inherent to this project, as smaller utilities do not usually have sufficient technical and financial resources to tackle this issue. These utilities will need to rely on the support of external partners that combine technology and expertise if they are to succeed. In addition, concerns about cybersecurity will lead the industry to demand appropriate security mechanisms to protect facilities and production processes from unauthorized access.

Globally, we expect an upsurge in projects related to productivity and optimal resource consumption in 2022. Intelligent asset management will be mainstreamed by the most innovative utilities, given the potential it has to boost efficiency and guarantee service availability.

Idrica’s Water Technology Trends 2022 report provides a comprehensive list of trends for the industry, including the Trends in intelligent asset management for 2022.

Read more Idrica Articles and News on H2O Global News. Do you have an article or video that you would like to share? Submit your article here or keep up with the latest news from the water industry and wastewater industry by subscribing to our weekly newsletter