A pioneering new smart greywater recycling technology has been installed at a prestigious new residential development in one of London’s most exclusive residential neighbourhoods. The innovative on-demand greywater recycling technology from water management systems specialist SDS is one of the first installations of the technology in the UK.

Meeting high standards of sustainability was a priority at 80 Holland Park, a new-build development by CPC Group of 25 individually-designed residences arranged across five villas within the Holland Park Estate, Kensington. The fully-serviced homes are served by a residents’ lounge and business suite, private screening room, swimming pool, and performance-driven training gym.

To meet planning and building control regulations, mains water demand was required to stay below a strict 110 litres daily allocation for each resident of the penthouses, duplex ‘town houses’ and loft style apartments.

80 Holland Park, a prestigious new residential development in one of London’s most exclusive residential neighbourhoods

On-Demand Smart Water Reuse

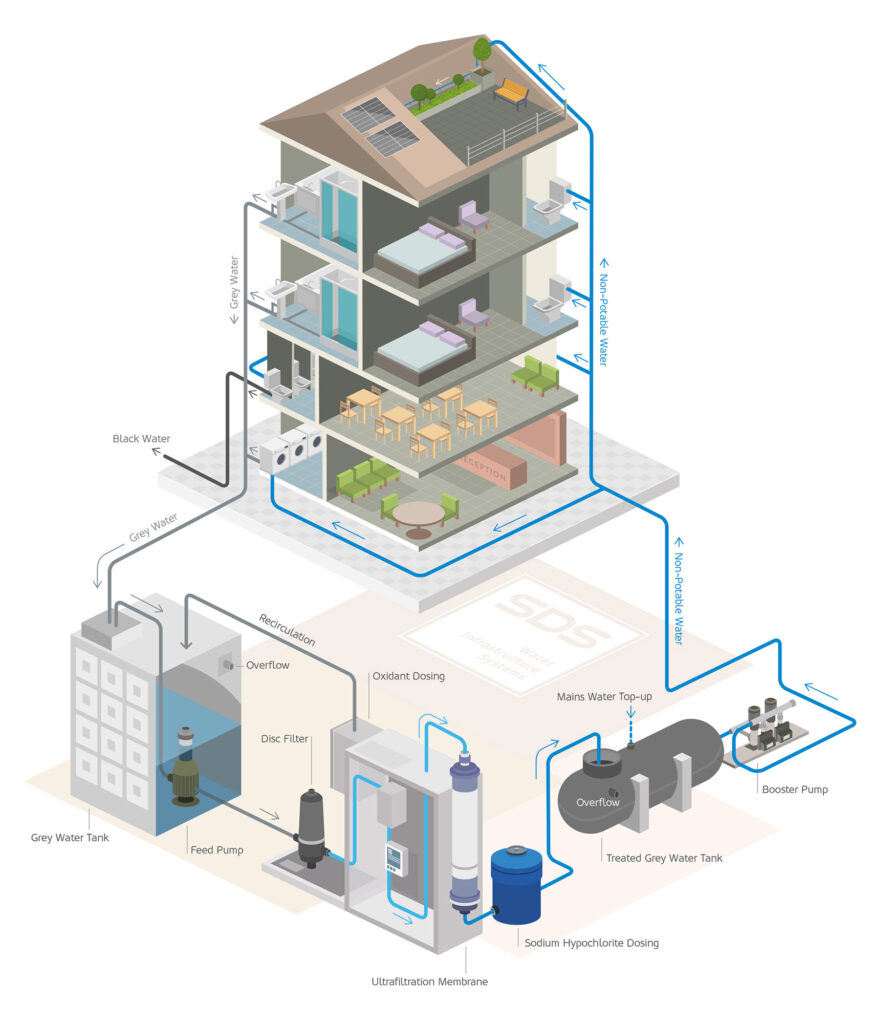

London-based consulting engineers chapmanbdsp specified the bespoke smart water system that enables the waste water from baths and showers to be collected, treated in the digitally-controlled greywater system, then reused for toilet flushing throughout the building.

By reusing water, the overall mains demand was calculated to reduce by at least 15% to an average of 90 litres per person per day, a very low level and significantly below the current national average of 140 litres.

Reduced Mains Water Demand

“In keeping with 80 Holland Park’s carefully-considered and individually-designed apartments, the bathroom fittings are of a very high specification,” explains Dave Honey, principle public health engineer with chapmanbdsp. “Greywater recycling is an efficient and sustainable technology that has enabled water that would otherwise have gone to waste to be reused, thereby offsetting the increased flow rates from the high-end sanitaryware.

“Planning conditions required the development to comply with Building Regulations Part G and the water efficiency criteria for new dwellings, normally 125 litres per person per day, but reduced further to 110 litres per person by a planning condition,” he added.

Collaboration between the chapmanbdsp engineers, SDS and the development’s environmental engineers was essential right from the design stage to exceed the required water efficiency performance and overcome the site constraints.

Accurate Usage Calculations

Honey explains: “The SDS team provided excellent expert support and produced clear calculations to show precisely how much water their system would process and subsequently provide. This information was also invaluable to our client’s environmental engineers to demonstrate the sustainable benefits of the development. By reviewing the full efficiency data, we could also be confident that the size of the system being specified was correct.”

The groundbreaking SDS Greywater on Demand system could fit in the building’s plant room much more easily than conventional membrane bioreactor (MBR) treatment, which would have been difficult to design around the constraints of the building, said Honey.

“By specifying the SDS Greywater on Demand System, the collection and storage tanks, which would be separate in an MBR system, could be combined to create a relatively small footprint. This meant the plant room could be located as centrally as possible and the pipework could also be routed without encroaching on the headroom requirements in the basement car park.

“The topography of the site meant it was difficult to collect waste water from all of the dwellings, unless we buried the system below the basement slab, which wasn’t feasible. We therefore had to ensure that the amount of water collected could yield sufficient to provide flushing for all WCs,” he added.

Ultrafiltration Greywater Technology

A bespoke smart water system that enables the waste water from baths and showers to be collected, treated in the digitally-controlled greywater system, then reused for toilet flushing throughout the building.

Waste water is collected from 27 outlets around the building via a dedicated network of pipes that are routed to a holding tank in the GWR basement plant room. The collected greywater is pumped through a disk pre-filter system and dosed with a small amount of chlorine before entering the ultrafilters. The ultrafiltration system is a highly-efficient hollow-fibre membrane with automated integral backwash that yields water to near drinking-water standards.

The treated water is then stored, ready for use, in a separate tank and pumped, as needed, to provide flushing of 88 WCs throughout the development. The estimated greywater yield per day is just over 3,000 litres when the development is fully occupied.

Honey adds: “Because of the ultrafiltration and treatment of the water, we could be sure the water is cleaned to a very high standard, even though its primary purpose is to flush toilets. It also ensures that no particles remain to damage valves on the system it serves.”

When combined with SDS’s smart SYMBiotICTM cloud-based data monitoring and control, the system can be configured to provide real-time performance measures, condition monitoring with alarms and alerts, as well as trend mapping to aid with preventative maintenance. Regular reports of water saving performance can also be output.

Offering high-performance efficiency in a smaller space, the SDS system reuses just enough water to be delivered efficiently throughout the building as it is needed. The scalability of the system means that recycled water can be provided from when the first residents move into the building, then adapt to increasing demand as more people move in. By contrast, an MBR system would require a minimum usage rate to be reached before it could be set in operation.

The long-term sustainability of 80 Holland Park has been considered throughout design and construction and also includes energy efficiency measures including an above-industry standard thermal envelope, the use of photovoltaic panels, a combined heat and power system, and communal lighting controls.

For more information, visit: www.sdslimited.com

Do you have a case studyto share? Click here to submit. If you’d like to subscribe to our weekly newsletter, click here.