Landia has seen a marked increase in demand for its wastewater JetMix system, with new orders received from two of the UK’s largest water companies.

The first, in the north, sees seven Landia JetMix units going into operation in sludge tanks, whilst in the south, a further nine mixing systems have also been specified.

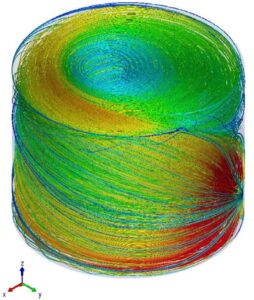

One of the many simple, yet highly effective mixing solutions from Landia, JetMix incorporates the first and original Chopper Pump (invented by Landia in 1950), fitted with jetting nozzles specially configured for each tank.

Howard Burton, Technical Sales Engineer at Landia, commented: “We were approached by a leading water company who expressed interest in Landia’s technology, and after many meetings and a raft of CFD modelling, they began their rolling programme of upgrades, appointing Framework contractors to handle each project. Around the same time, the other water company was embarking on a major upgrade of one site, and they too chose Landia JetMix. It is very encouraging to see that water companies are embracing the benefits of low energy usage and total cost of ownership from a product that will give long-lasting, reliable service.”

Previously, at Glatfelter, the leading global supplier of engineered materials, Landia’s JetMix replaced a very troublesome mixing system for an open-topped 1000m3 above-ground (7m) glass-lined steel tank used for pH correction.

The mixer that was replaced was extremely cumbersome to retrieve, causing health & safety issues and significantly costly downtime due to numerous breakdowns. Now, the retrofitted Landia JetMix ensures that there is no build-up of crust in the centre of the tank, which regularly used to clog up the old pump.

Following the success of the first JetMix system, Glatfelter invested in a further four Landia units, two for a 1500m3 vessel, one for a 500m3 tank, and one for a below-ground 150m3 pit, solving significant crusting issues.