An overabundance of phosphorus in water can cause a number of adverse ecological effects. Traditionally, chemicals have been used for P removal. But a new process of removing phosphorus from wastewater using algae is becoming more and more established.

Here, Matt Baldry, Director at I-Phyc, compares the chemical and biological approaches to P removal.

Chemical Treatment with Ferric Sulphate

Historically, the wastewater industry’s most relied upon method to remove phosphorus in wastewater discharges has involved metal salts, typically Ferric Sulphate. Ferric is used to react with soluble phosphates to form solid precipitates that are then removed by solids separation processes including clarification and filtration. To reach the discharge limits set out in the more recent Asset Management Plan periods, often a double dose of Ferric Sulphate is required – known in the industry as two-point dosing – followed by Tertiary Solids Removal.

Ferric Sulphate Treatment – Pros

This approach is a tried and tested method that the industry is accustomed to. It is capable of reducing phosphorus levels down to 0.5mg/l at larger plants, and it has been shown to reduce levels to 0.25mg/l in some cases.

Ferric Sulphate Treatment – Cons

With consent limits for phosphorus tightening up, there is a question as to whether Ferric Sulphate treatment is a long-term, sustainable solution. Trials in AMP 6 indicated that 0.25mg/l is at the very limit of what chemical dosing technology is capable of.

For smaller plants in particular, it’s often a struggle to reach levels of 0.5mg/l with Ferric Sulphate dosing. This can be because the variable flows that smaller plants experience make it difficult to provide a consistent approach to dosing. Also, the standard of existing assets, such as settlement tanks, clarifiers and sludge holding tanks, are not always sufficiently sized to handle the increase in solids produced by the use of ferric. As a result, operators can struggle to find the balance of achieving the phosphorus consent while using chemicals economically.

Given that ferric is an iron-based chemical, workers in treatment works need to bear in mind the maximum iron discharge allowance, which is usually around 3.5mg/l to 4.0mg/l. As it stands, this relatively high concentration of iron is seen as a necessary evil in the context of phosphorus removal. However, this isn’t to say that a requirement to reduce iron entering the UK’s watercourses isn’t to come soon. The reality is that using Ferric Sulphate to simultaneously treat wastewater to be low in phosphorus and iron ferric is very difficult and in practice, is sometimes not really viable.

Another flaw with Ferric Sulphate is that it’s incredibly acidic. This means that when used in processing wastewater, the pH is reduced beyond acceptable limits. In this case, additional chemicals might be required to neutralise the wastewater, adding another layer of complexity to the process.

And what about the health and safety concerns that come with chemical wastewater treatment? Operators must follow strict regimes during the filling of tanks and maintenance of dosing equipment, wear protective clothing and incorporate emergency showers onsite. A spill of Ferric Sulphate is hazardous, both to workers and the environment at large.

It is also worth noting the demand for Ferric is currently increasing at an exponential rate and the supply chain will be challenged not just to satisfy the demand but also to supply at an affordable cost, chances are the cost will only go one way!

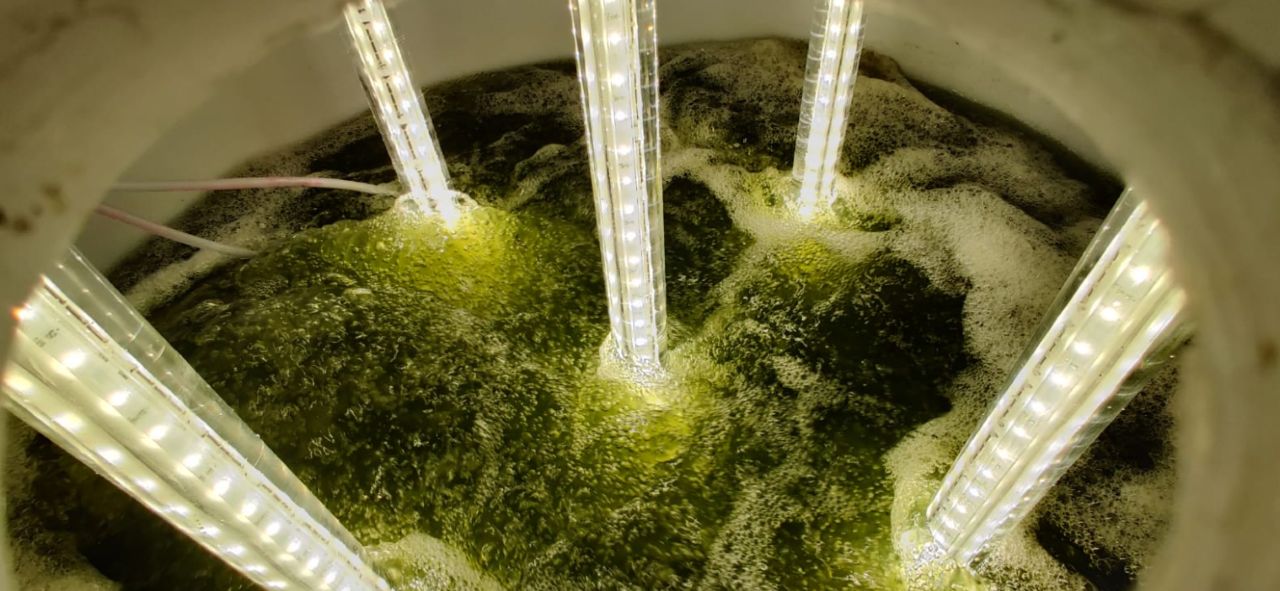

Bio-P removal with MircoAlgae

Bio-P removal is a relatively new technology that harnesses the natural power of microalgae to remove phosphorus to levels beyond the limit often required in AMP7.

Microalgae-based Treatment – Pros

Here are a few benefits that come with harnessing Microalgae for wastewater treatment:

- It’s a chemical-free process – it presents no threats to operators or the environment. Plus, no iron is discharged into the environment.

- It’s also capable of almost total removal of ammonia; for sites with a combined phosphorus and ammonia consent this is incredibly useful, eliminating the need for SAF plants for HRFs

- There’s no need for additional chemicals to correct the pH of the effluent

- There’s no sludge production – existing assets are unaffected by the process and there are no additional transportation and disposal costs.

- There is a small production of excess microalgae, but this is harvested off as a resource in a way that phosphorus (and nitrates in the ammonia) are not lost but can be reused in a circular economy

Microalgae-based Treatment – Cons

The main con is that it’s a new technology and so the water industry needs some time to get its head around it. It can be difficult to change the ‘tried and tested’ mentality, but with time, and given we’re all more environmentally aware than ever, the water industry is likely to come round to the idea of change.

In fact, I-Phyc’s microalgae-based method of removing phosphorus from wastewater has already been rolled out at sites with consent.

A Final Word

The reality is that Ferric Sulphate is at its limit for the amount of phosphorus that it can remove in wastewater. With stricter regulations continuing to come in, such chemical treatment is not a sustainable solution. Natural alternative approaches have arrived on the scene and are here to stay.

To find out more about harnessing the power of microalgae in wastewater treatment, visit www.i-phyc.com

[…] Natural Water Treatment: The Way Forward […]