Most small to medium wastewater facilities in the United States (<50 MGD) are operating as end-of-pipe treatment plants with little or no recovery of resources. They are using ~ 3% of our electrical load, or about ~2300 kW-h per million gallons of sewage treated. The majority are using an activated sludge process to degrade organics, nitrify ammonia to nitrite and nitrate. At some plants, denitrification is performed converting nitrite and nitrate to N2. In rare cases, phosphorus, a finite resource, is managed and recovered through enhanced biological phosphorus removal.

374Water, of Durham, NC, USA, is commercializing a novel approach to Supercritical Water Oxidation (“AirSCWO”). It has the potential to shift the wastewater paradigm from end of pipe treatment to resource recovery. It harnesses energy embedded in the waste stream undergoing treatment, while enabling recovery of clean water and minerals, paving the way for efficient resources recovery from all kinds of sludges and biosolids. The process is fast, clean and a net energy producer. Moreover, the benefits of SCWO empower organizations to achieve the United Nations Sustainable Development Goals (SDGs).

SCWO for Resource Recovery

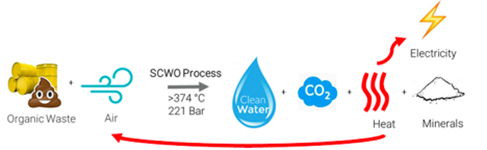

Supercritical water oxidation is an advanced oxidation method that relies on the unique reactivity and transport properties of water when the wet wastes are brought above the critical point of water (374 °C and 218 atm, or 705 °F and 3200 psi). According to Tassaing, Danten, and Besnard in the November 2002 Journal of Molecular Liquids, supercritical water is a dense single phase with transport properties similar to those of a gas, and solvent properties comparable to those of a non-polar solvent. When oxygen is present, it is fully soluble in supercritical water, resulting in extremely rapid and complete oxidation of all organics to carbon dioxide, nitrogen gas, clean water, and mineral salts. The heat from the oxidation reaction is recovered and used in part to heat the influent stream while the excess heat is converted to electricity (Figure 1).

Supercritical Water Oxidation (SCWO) Reaction Equation

Depending on the concentration of the feedstock, reactors can be operated auto-thermally (i.e., no outside input of heat is required). Typical reaction times are in the order of 2-10 seconds allowing much smaller systems for the same throughput, making it possible to build systems that are compact compared to other technologies. The process does not generate harmful by-products such as NOx, SOx, VOC, or odors per Bermejo and Cocero in their article, “Supercritical Water Oxidation: A Technical Review,” published on September 6, 2006 in the Journal of the American Institute of Chemical Engineers. Ammonia and organic nitrogen in the waste undergoing treatment are converted to nitrogen gas, while phosphorus precipitates as phosphates and can be recovered. The amount of CO2 generated is less than what is currently generated by the current approach to handling sludges and biosolids.

The Benefits of AirSCWO

The value of AirSCWO to destroy organics and recover resources in wastewater sludge and biosolids has dramatically increased due to the ubiquitous presence of emerging contaminants such PFAS, 1,4-Dioxane, microplastics, pharmaceuticals, and other refractory chemical compounds. Landfills are refusing biosolids that do not meet the strict regulatory requirements for land application. A strong case can be made for AirSCWO as a superior treatment and resource recovery technology. AirSCWO can favourably replace existing anaerobic systems or can provide on-site solids handling with resources recovery at smaller plant that do not have anaerobic digestion.

For more than 25 years, technical challenges have slowed down commercial deployment of supercritical water oxidation. Corrosion, plugging and fouling are the common issues and linked to the complex nature of a high-pressure, high-temperature process. Critical design elements to overcome these challenges include reactor material, reactor shape and size. The form of oxygen used is another issue as pure oxygen handling and storage introduces a process hazard causing safety concerns and increase capital expenditures to design in appropriate safety controls. Another obstacle to commercialization of supercritical water oxidation has been an unrealistic goal of producing power at a competitive retail electricity rate ($0.3-0.5 per kWh). This has been out of reach and the cause of numerous failures.

Research and development efforts at Duke University by the founders of 374Water, Marc Deshusses and Kobe Nagar, have resolved the issues of corrosion, plugging, fouling and the use of pure oxygen, paving the way for commercial deployment of supercritical water oxidation. Duke University designed and built a pilot version of the AirSCWO system in a standard 20-foot shipping container (“Nix1”). The Nix1 processes up to one (1) ton of sludge at 10-20% dry solids content, which is the equivalent of fecal matter from about 1000 persons per day. The pilot system resides at Duke University has been operating since early 2015, and undergoing design optimization and testing

AirSCWO is a novel approach to supercritical oxidation. During recent PFAS elimination work with US EPA, AirSCWO was informally called “the 3rd generation of supercritical water oxidation). It has pending U.S. patents that address prior hurdles by incorporating moderate preheating of the waste slurry, followed by mixing with supercritical water and air. Air serves as the oxidant, a much safer alternative to pure oxygen. The internal mixing rapidly brings the waste undergoing treatment to supercritical conditions thereby minimizing corrosion and the risks of waste charring and plugging. All organics in the sludge are rapidly oxidized to CO2, while the heat of oxidation is recovered to heat the influent waste. The other critical innovations instrumental in overcoming corrosion, plugging and energy efficiency challenges is a multi-stream tubular reactor configuration that enables efficient and sustainable treatment.

Each AirSCWO unit is containerized in shipping container, 20 foot for the Nix1, 40 feet for the Nix6 unit, and three 40 foot for the Nix30. This makes the AirSCWO compact and modular allowing it to integrate into the existing footprint of a wastewater plant. Units can be set up to operate in parallel, offering a number of configurations to satisfy the different throughput requirements of each unique wastewater plant. As part of our design and planning process, capital and operating expenses were evaluated for different sizes. The system is automated using sensors connected to a SCADA system and process historian for real-time analysis of trends, key process indicators (KPIs) and performance measurements.

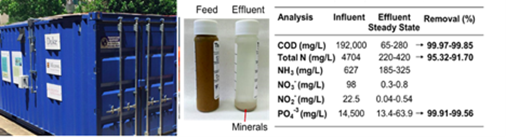

Figure 2 shows the Nix1 pilot unit at Duke University; samples of typical influent and effluent; and a table with characteristics of influent and effluent for a typical biosolids run. A video of the operating Nix1 is available here.

Duke University Pilot System (left), biosolids slurry and treated effluent and its characteristics.

AirSCWO has successfully processed primary, secondary, and digested sludge slurries, and a range of other feedstocks including landfill leachate, and sludge streams comingled with waste oil, food wastes, and plastics. The results so far show very rapid treatment with >99.9% conversion of organics to water, energy, CO2 and mineral salts. Total nitrogen and phosphorous removal were over 80% and 95%. Pharmaceuticals, PFAS and other trace organic contaminants are destroyed with greater than 99.9% efficiency. All microorganisms and pathogens are eliminated.

The projected total for biosolids is $50 per wet ton at the Nix30 scale (~30 wet tonnes/day) with a majority of the cost coming from amortizing the equipment. This cost is already competitive although the benefits of resource recovery (fertilizer, heat, and carbon credit) are not factored in those estimates, as their true value has not yet been evaluated. These cost projections make the SCWO process very competitive compared to anaerobic digestion and dewatering followed by offsite disposal by land application, landfilling or incineration.

Invent the Future – Water Resource Recovery with SCWO

AirSCWO has the ability to transform wastewater treatment plants (WWTPs) to Water Resource Recovery Facilities (WRRFs). The process recovers water, energy and phosphorus from wastewater sludge and biosolids while reducing the volume of solids by >98%. AirSCWO eliminates the methane generated by anaerobic digestion and GHG emissions from trucks hauling residuals offsite. It destroys emerging contaminants like PFAS and 1,4 dioxane, pharmaceuticals, microplastics and antibiotic resistant bacteria, eliminating public health concerns and financial liabilities.

Air SCWO reduces operational expenses. The energy bill is lower. Off-site transportation handles a lower solids content than the biosolids prepared for off-site hauling and disposal. Finally, AirSCWO does not require side-stream processing to achieve total nitrogen discharge compliance since, unlike anaerobic digestion, the SCWO process does not generate ammonia-rich filtrate residuals.

Authors:

Marc Deshusses, CTO, 374Water Inc. and Duke University Professor and Researcher

Doug Hatler, Environmental Engineer, 374Water Inc. and President of Environmental Business Ventures.

Kobe Nagar, CEO, 374Water Inc. and Duke University Researcher

Do you have an article that you would like to share? Submit your article here or keep up with the latest news from the water industry and wastewater industry by subscribing to our weekly newsletter.