Exclusive interview: We sat down with Dr. Jo Burgess, Head of the Trial Reservoir at Isle Utilities, to find out more about the programme and how it is accelerating innovation in the water sector.

What is Trial Reservoir and how does it work?

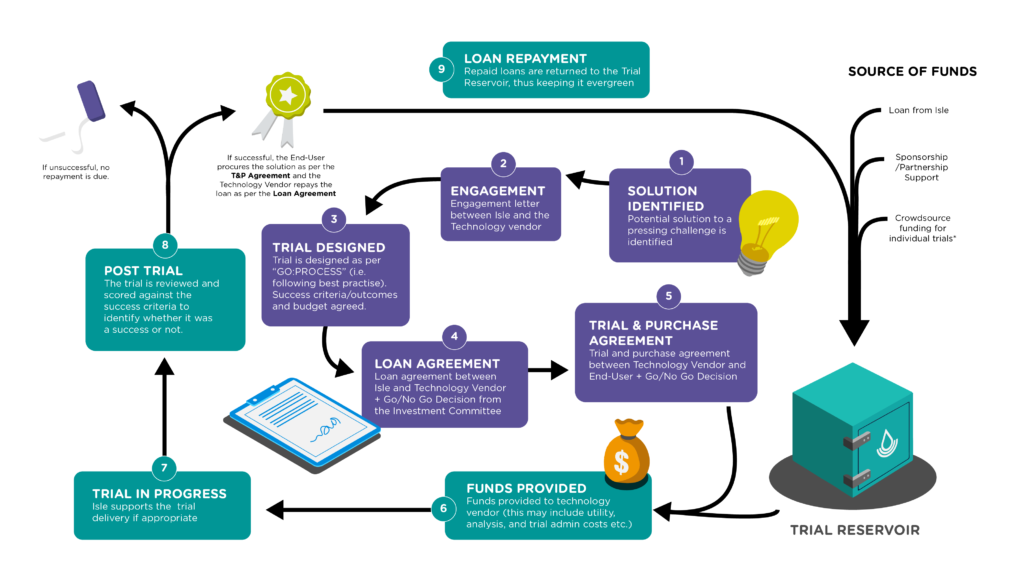

The Reservoir provides financial assistance to support trials of new technology on the understanding that if the trial works the end user or utility must buy the technology. It’s a blend of a technology accelerator, a loan financing instrument, and a technical support system.

The Reservoir is partly funded by sponsors plus quarter of Isle’s own profits. The money goes into a pool – the Reservoir – we use this to give loans to technology developers to carry out trials in collaboration with end users.

The loan either gets written off if the trial doesn’t meet its success criteria or it’s paid back with interest which is funded by the utility who is buying the technology if the trial works.

The Reservoir´s revolutionary approach de-risks the trial for the utility, bridges the funding gap for the technology company and helps ensure that the utility commits to meaningful action if the trial is a success.

How the Trial Reservoir works

Designing and validating technology trials is routine work in the consulting side of Isle; in the Reservoir we do this work on a non-profit basis. There are three conditions trials must satisfy to come into the reservoir: 1, there must be climate change mitigation benefits, 2, a trial and purchase agreement committing the end user to procuring something if the trial is a success and 3 measurable key performance indicators (KPIs) for the trial that enable the end user to decide whether to implement the technology or not. The technology developer and the end user agree on these KPIs at the start of the trial, with our help.

Then we support the trial with technical expertise. If the trial succeeds, the end-user implements the innovation and the technology developer repays the loan.

If despite everyone’s best efforts, the trial fails, the user doesn’t have to procure anything and we write off the loan. We take the financial risk.

What are the main water sector challenges the initiative was designed to tackle?

The most serious and urgent issue facing us today is climate change. The primary reason for creating the Reservoir was to accelerate the response to climate change by helping technologies that can mitigate it penetrate the market; bringing technologies to market in the water industry is extremely difficult.

Most people in the water industry or in innovation in any industry have heard of the so-called “valley of death”. The water sector is extremely risk averse which means that technology start-ups end up caught in a cycle of trialling and trialling again without ever making a sale.

In many utilities, innovation is done in a separate part of the business and lacks executive support. To mitigate this situation, the Reservoir requires a Trial and Purchase Agreement between the technology vendor and end-user to be in place prior to the trial. This ensures that there is a plan for roll-out across the business that includes operations staff, finance officers and central ops.

How have the trials gone since the launch of the project? What are some of the lessons learnt?

To date, five trials have concluded, of which four were successful. Three are currently under way, and there are eight close to starting with a further 30 in the planning stages.

Let’s talk about the unsuccessful trial first. The trial loan was used to build 20 units of a smart device for water flow measurement with metering and billing via a smart card, similar to contactless card payments. The end user was a water kiosk business, and a few weeks into the trial it became clear that the devices were not as well suited to the working conditions as we all expected. The kiosk business could not use the devices, so their commitment to purchase several hundred of them fell away, and the technology developer has not had to repay the loan.

This isn’t the end of the story, though. We continue working with the technology developer to improve the device design, and to help identify a new end-user whose operating conditions are appropriate for the devices.

Success stories:

eWATER Services

eWATER Services‘ advanced system of water provision, delivery, and billing utilises solar energy and gravitational force to deliver safe drinking water to people in The Gambia who previously did not have access. “SmartTags” are used to enable “SmartTaps” to release the water and debit credit for it. Trained technicians in the locality look after the system, while local shops provide credit. This trial run provided 500 individuals in two villages with potable water, getting rid of the need to travel to a river, fetch water, and boil it at home to make it safe to drink. Each litre of water conserved 3.03kg of CO₂e emissions by avoiding the use of fossil fuels.

| Tap ID | Mean L /day dispensed during trial | kg CO₂ saved during trial | Projected CO₂ saving tonnes/a |

| Wellingaraba 1 | 1,467 | 746,762 | 1,623 |

| Wellingaraba 2 | 1,387 | 706,038 | 1,535 |

| Ndemban | 1,725 | 878,094 | 1,909 |

| Total | 2,330,894 | 5,068 |

School and workplace absenteeism declined owing to a reduced burden of disease, and school attendance by girls in particular increased, because the task of collecting water is traditionally carried out by girls. You can if you wish hear about the carbon savings and other benefits described by Isle, eWATER staff, and some customers here. A live data dashboard showing water dispensed and CO₂ saved can be seen here.

Orége Ltd

Orege/Yorkshire Water flocculated sludge SLG process.

Orége Ltd’s solid-liquid-gas (SLG) technology thickens sludge to ~5% dry solids, higher thicknesses than traditional equipment, but the sludge is still pumpable and with high quality filtrate. Orége’s SLG technology thickens debris up to around 5% dry solids, which is more than what old-style machines can do. But the sludge can still be pumped, and the filtrate it produces is of high quality.

The quantity of sludge that needs to be transferred is usually cut in half, which decreases the carbon footprint and operational expenses of transporting it. Yorkshire Water conducted a trial at Seamer, where minimal construction was necessary, with one SLG unit. The unit performed well, resulting in a consistent 50% reduction in sludge volume with no complications to the upstream or downstream process on the site. This means a six-figure operational savings for Yorkshire Water over the lifetime of the asset, in addition to a yearly reduction in carbon footprint of the sludge tankering operation of 120,000kg CO₂e. There are additional advantages as well, including decreased traffic congestion, which brings down fuel usage by other vehicles, leading to reduced noise and air pollution in the region.. If you wish, you can watch Matthew Gibson, business development director at Orège Ltd and Yorkshire Water’s biosolids manager Richard Glossop in a joint interview on the trial and their next steps to roll SLG out across the business here.

The collaborative efforts of Reservoir sponsor and technology user Xylem have led to a successful trial of the Transcend Design Generator (TDG) for the purpose of creating multiple complete wastewater treatment works design possibilities. The TDG has the potential to reduce the ecological footprint. Sahil Chaini of Transcend and Elma Kapa from Xylem discussed their trial together in an optional viewing here. Xylem’s trial in Australia revealed that their engineers were able to cut the time required to create end-to-end designs in half, and could indicate the lowest carbon footprint of construction, the lowest carbon footprint of operation, or the lowest overall environmental impact when making use of the TDG.

Advantageous Systems (ADS)

ADS system on site in Fresco, California

In order to analyse the effectiveness of Advantageous Systems’ (ADS) MPT technology, a trial was conducted to treat well water for agricultural use, specifically targeting the extraction of boron prior to a reverse osmosis (RO) system. Linneman Ranches, a business that grows tree nuts, primarily almonds, needed to irrigate their orchards during dry seasons with borehole water, however the groundwater in the area has an elevated TDS content, as well as a high concentration of boron that needs to be reduced to 1.5-2.0 ppm so that it is suitable for the crops. The primary goal was to significantly reduce the electrical power needed by the RO by not requiring a second pass membrane.

The trial KPIs were met: the pilot system treated a feed flow of untreated well feed water at a blended rate of 2,000 gallons per minute, and the treated water quality met the required limits for TDS, boron, chlorides, and sodium. Over 90% of the feed water was recovered as treated water with <10% reject. The average electrical consumption was <740 kWh per acre foot of water produced, providing an energy saving of 510 kWh p/m at the trial site, equivalent to offsetting 0.23 tonnes CO₂e p/m. As a result, Linneman Ranches are keeping the unit and have contracted ADS to handle all operations, maintenance and troubleshooting as a turn-key installation.

What makes a trial successful or not?

Our due diligence process focuses on three aspects: the technology, the technology vendor, and the end-user. A successful trial needs a scientifically credible technology, a reliable vendor, and an end-user who can drive the trial-to-purchase process internally.

The trial needs to be deigned in such as way as to answer the questions the potential client must ask in order to decide whether to use the innovation, or not. It’s critical for the tech developer to grasp the difference between an R&D pilot trial, and the type of trial run for a specific end-user. Isle can help with the trial design – it needs to be no longer than necessary, but long enough and data-rich enough to be conclusive.

The critical success factors (CSFs) and KPIs for each trial need to be defined and agreed between the end-user and tech vendor at the beginning, before the trial starts. And the KPIs absolutely have to be quantitative. Again, Isle can help end-users articulate their required CSFs and translate those into numerical KPIs that the technology vendor can review and work with.

Finally, an innovation champion within the end-user organisation is critically important. Selling something other than business as usual upwards in the utility is difficult, and technology developers don’t have insight into the end-user’s internal budgeting cycles etc. that can scupper a trial or allow it to take off.

Why is the Trial Reservoir such a valuable programme for the water sector?

It is currently the ONLY technology accelerator which guarantees a sale in the event of a successful trial. It’s the only one that provides loans as well as expertise, and provides an independent opinion on the trial results to the end-user.

Successful trials are collaboratively publicised by Isle in partnership with the end-users and technology developers, providing them a platform that reaches several thousand water professionals in 109 countries – the peer learning offered by having the end-users’ voices opens the door to hundreds of potential second adopters. In addition, it enables the end-users to speak about the concrete steps they are taking towards their own net zero carbon goals in a public forum which has many of the world’s water sector regulators among its audience.

What does 2023 hold?

For the original climate change Reservoir – more of the same. Much more! The first year has taught us a great deal about the pitfalls and smart moves, and we intend to scale up our activity.

In December, Isle partnered with IDB Labs, the innovation laboratory of the Inter-American Development Bank Group, in co-funding an innovative technology accelerator mechanism for water utilities in Brazil to find and deploy promising innovations. The partnership is a new approach to funding and scaling breakthrough water technologies specifically in Brazil, called the “Brazil Trial Reservoir.” It provides water technology innovators access to capital for pilot projects, with an initial focus on technologies that increase the efficiency and reduce the carbon emissions of water treatment systems. Technology trials and pilots are generally required in advance of full-scale implementations. The Brazil Trial Reservoir will make a dedicated pool of funding available to early-stage technology companies, giving them the capacity to undertake trial deployments with Brazilian water utilities.

In addition, there are ambitious plans afoot to launch two more Reservoirs: one focused on Industrial Water, and one for the energy industry.

Isle is building an Industrial Reservoir alongside founding sponsors Xylem and Aqualateral, to create a step-change in innovation for circular economies in a broader sense. The focus here will be Advanced Industrial Treatment solutions addressing resource recovery, emerging contaminants, waste-to-energy/circular economy & decentralisation. We are seeking partners to contribute $100K per year to the Industrial Reservoir, which aims to accelerate 3+ trials/year to full-scale implementation and support $1 million per year worth of trials; this will reduce pilot-to-implementation time by 80%. Dave Flinton, Chief Innovation, Technology, and Products Officer at Xylem, said of the Industrial Reservoir, “We believe that making this a cross-industry collaborative effort is imperative because, as the saying goes, “a rising tide lifts all ships”.

Finally, Isle is preparing a Reservoir-style for the energy industry with a focus on the transition to renewables and lowering the carbon footprint of power grid infrastructure.

Related articles:

Water sector must invest in our planet