SCADA is the acronym for Supervisory Control and Data Acquisition. SCADA is a computer-based system for gathering and analyzing real-time data to monitor and control equipment that deals with critical and time-sensitive materials or events. SCADA systems were first used in the 1960s and are now an integral component in virtually all industrial plant and production facilities including water and wastewater utility systems.

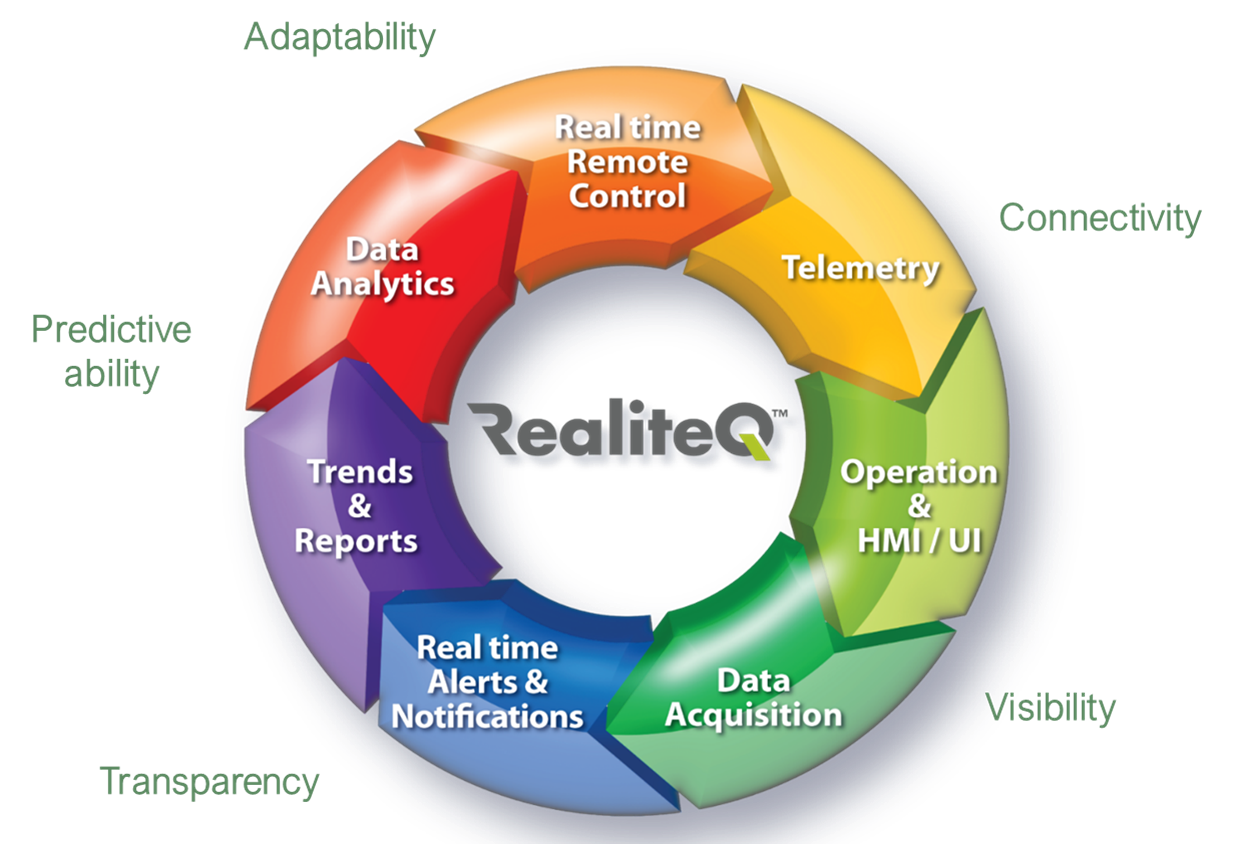

Industry 4.0 is characterized by using digital technologies such as big data, analytics, artificial intelligence, virtual reality, and the Internet of Things (IoT). The goal of Industry 4.0 is to use automation for industrial processes to create greater efficiency and increased productivity. Cloud-based SCADA software enables companies to monitor and control their industrial processes remotely. It allows for the collection and analysis of data in real-time to facilitate automated decision-making.

Organizations can use cloud-based technology to reduce operational costs, improve safety, and increase efficiency. One of the most obvious benefits of using a cloud-based SCADA system (4G SCADA) is cost savings. Organizations can utilize the cloud to avoid the cost of purchasing, installing, and maintaining hardware and software while reducing energy consumption. Additionally, these systems are highly scalable, allowing organizations to add or remove resources on demand, further reducing costs. 4G SCADA systems can detect potential issues by providing real-time monitoring and data analysis before they become dangerous. Additionally, 4G SCADA systems can provide remote access and control, allowing personnel to monitor and adjust operations from a safe distance. By automating routine tasks, SCADA systems can free up personnel to focus on more complex tasks. Additionally, the system can provide real-time insights and data analysis, allowing personnel to make more informed decisions faster. A few common challenges must be addressed when considering a 4G SCADA system: security, data privacy, and connectivity. SCADA security is one of the most important issues associated with cloud-based monitoring systems. These systems are typically accessible remotely, meaning the data and control systems must be protected from unauthorized access. Data privacy is also a major concern, as the data collected and stored on the cloud must be kept secure and confidential. Remote monitoring systems rely heavily on connectivity. Without a reliable and secure connection, these systems can’t operate effectively. Organizations must ensure they have the proper infrastructure and resources to access the 4G SCADA system when needed.

The water and wastewater industries are increasingly turning to 4G SCADA systems to improve their operations. From automated monitoring of water quality to real-time data analysis and decision-making to remote access and control, 4G SCADA systems are an essential tool for the successful operation of these industries. 4G SCADA systems can automate water quality monitoring, providing accurate and timely data that can be used to make informed decisions. This data can be used to detect any abnormalities in water quality and to take corrective action. It can also provide real-time data analysis, allowing for more informed and intelligent decision-making. This allows for remote monitoring and management of operations and remote problem-solving. 4G SCADA systems enable remote access and control of water treatment and wastewater collection systems. It also enables the sharing of data and information between different locations and stakeholders, which can help to improve efficiency and collaboration. Ultimately, 4G SCADA systems can benefit any industry, but their role in the water and wastewater industries is particularly important.

Mexico City is facing a severe water shortage, with some experts warning that the city could deplete its water supply in 2024 if conditions do not improve. With “Day Zero”, the day when water taps run dry for large portions of the city, looming, urgent action is imperative. Utilities in the area are aware of this issue and some have been taking steps to alleviate the stress.

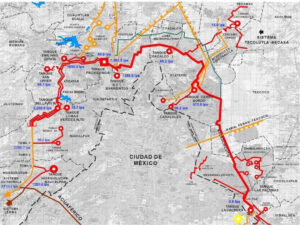

The Water Commission of the State of Mexico – CAEM, is a decentralized public entity known as the “State Commission for Water and Sanitation,” with its own legal status and assets. Its general purpose is to build, maintain, operate, and manage potable water and sewer systems for the benefit of urban and rural communities in the State of Mexico. Essentially, it is responsible for the distribution of potable water in the State of Mexico and its municipalities, and thus operates specialized facilities for the storage, distribution, and exploitation of potable water wells. The system is primarily supplied by four sources: the Cutzamala System: 260 ML/day (68.4 MGD), the Lerma System: 130 ML/day (34.2 MGD), the Madin Dam: 43 ML/day (11.4 MGD) and the Barrientos System: 121 ML/day (32 MGD). The system consists of 20 storage tanks with a capacity between 1000 and 50,000 m³ (0.25 MG to 13 MG), 4 pumping plants with a capacity ranging from 9 to 173 ML/day ( 2.5 to 45.6 MGD), 56 deep groundwater wells and the three major pipeline circuits crossing the state of Mexico. The system can deliver 518 ML/day (137 MGD) with the groundwater wells supplying up to 173 ML/day (45.6 MGD). Local municipalities have concessions to utilize natural water sources in their territories such as lakes, lagoons, rivers, and wells under the supervision of CONAGUA. It is estimated that the population receiving potable water from CAEM installations is 15 million people.

CAEM was introduced to the technology offered by RealiteQ through prior work with a local solutions integrator, APRA. A plan was proposed to eliminate the operational risk of tank overflows due to operational errors. The proof-of-concept project automated the operations of a 15,000 cubic meter storage tank that serves 1.4 million people. The tank’s fill level

was automated, along with the telemetry of the inlet flow, outlet flow valves, and three local pumping areas to municipal tanks that supply four highly saturated urban areas. Manual measurements were replaced with a complete set of digital sensors to obtain tank levels, start and stop pumping equipment, monitor engine vibration ranges, gather data from various

flow meters installed in the network, and automated valves to control flow based on operational directives defined by CAEM management according to water distribution needs. Since then, the Cerro Gordo tank has been remotely controlled in real-time and operates autonomously according to operational guidelines, minimizing personnel intervention. As a result, there have been no tank overflows since it began operating automatically through the RealiteQ platform.

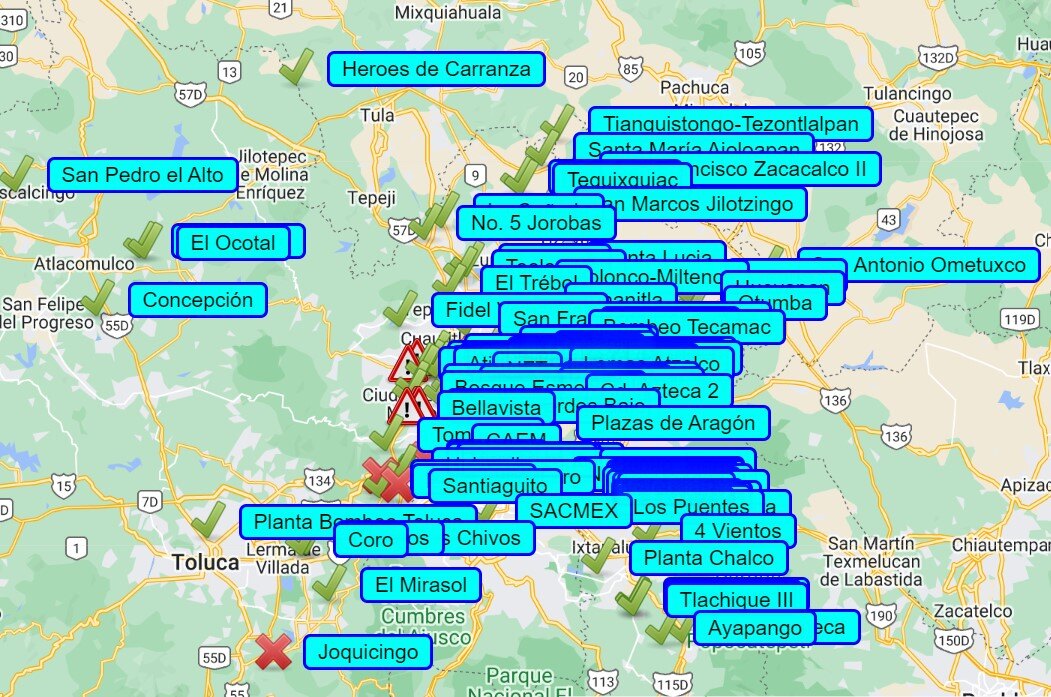

Based on that success, additional facilities were added to the RealiteQ cloud-based SCADA system. In 2020 the remote operation of 20 storage tanks and their respective distribution lines was automated. These assets are spaced 20 to 50 kilometers between storage points or distribution valves covering almost 200 km of pipelines of various diameters. In 2022 32 valves were automated to ensure water distribution to all 16 connected municipalities. Valves control flow based on delivery objectives set by the utility. Valve automation allows for equitable water distribution, avoiding the effect of more water going to municipalities closer to federal delivery sources.

In 2023 the 56 deep groundwater wells managed by CAEM and serving 35 municipalities were integrated into the system. The wells are the second most important source of drinking water for the state of Mexico. Real-time simultaneous information is now available on the extraction volumes of each well. Their operation is completely remote. Information on energy consumption and eight other related variables such as power factor, active and reactive power, voltage, etc., is available. The dynamic and static level as well as the outlet pressure and temperature are known.

Real-time data on daily production from each well, each region, and the State of Mexico is available to all partners. The monitoring of 63 meteorological stations geographically dispersed throughout the State of Mexico was also incorporated into the platform. Prior to their integration into the RealiteQ platform, each regional management sent personnel once or twice a month to remote locations to collect data from each station. This involved significant operational expenses in personnel mobility and man-hours for data collection. Currently, all climate-related information generated by the meteorological stations is available in real time.

Today, CAEM has real-time information on the production capacity of its wells and the bulk water delivery to the municipalities of the State of Mexico, providing transparency in potable water distribution. An important example of the scope of the RealiteQ platform is that it allows real-time information sharing anywhere. In 2023, due to the decrease in stored potable water levels in the main sources of water in the State of Mexico, CAEM decided to start sharing strategic information directly with the municipalities. User profiles were created for them to access the platform and the information on the volumes of water they are receiving from CAEM.

Communication and coordination between different field and administrative areas have improved by sharing real-time information on the operational performance of each installation. Emergency response times have also improved, allowing CAEM to respond to communities more swiftly.

Different monitoring dashboards have been developed to meet the specific needs of various user groups, from senior management to field personnel. Each user group has visibility into the information relevant to their work execution.

APRA is a Mexican company dedicated to offering end-to-end comprehensive solutions. The collaboration model designed for CAEM is an integral service that develops the process automation plan, transitioning from manual/analog to digital operation, and is responsible for the equipment, maintenance, and replacement of all necessary components for the operation of the automation system. This ensures that each component functions adequately and that those that fail are replaced as quickly as possible, ensuring uninterrupted operation once a facility is automated. Additionally, APRA handles all the design work of automated processes and their programming, as well as the initial configuration of the platform and the multiple control dashboards. The service is complemented by ongoing training for users authorized by CAEM management.

Currently, CAEM controls via the RealiteQ wide range of facilities including:

- Water storage tanks with capacities up to 50,000 cubic meters

- Water conveyance lines with diameters up to 60 inches over dozens of kilometers

- Pumping plants

- Monitoring of pressure in conveyance lines at critical points

- Automated valves controlled by target flow or specific volume across different communities or urban areas

- Deep potable water wells where the production of each installation and the status of their assets, such as pump motors, are monitored

- Water Treatment Plant

- Weather stations for monitoring climatological variables, mainly rainfall

- CAEM has achieved, among other things:

- Eliminating the overflow of storage tanks

- Reducing emergency response times

- Operating water distribution circuits remotely

- Having information on operational trends of different installations

- Sharing critical potable water availability information with municipalities.

The communication between different CAEM’s areas improved given a better, quicker and accurate information flow about several performance operative variables produced at facilities level. There is better control and efficiency in water distribution. Target flows can be determined at specific times and areas of the city based on hard and accurate data in real time through the use of the RealiteQ Central Management On line Portal. There is improved relationship with community leaders. Accurate and reliable data can be shared with the community and its representatives about the flows that are delivered in certain periods of time at different seasons of the year and demonstrate compliance with the agreed commitments. Flows in different pipelines can be adjusted simultaneously and in real time from a central management portal giving CAEM the ability to respond immediately to the demands of the community. Maintenance costs are reduced. Total offline hours at facilities are minimized due to failure of pumping equipment. With the RealiteQ platform it is possible to permanently monitor the main performance variables of the pumping equipment and determine in advance when any equipment requires repair. The risk of flooding of facilities has been eliminated due to sudden excess inflows that are greater than storage tank capacity.

The use of the RealiteQ Platform allows the operation of facilities in a safer environment for our collaborators. Prior to RealiteQ, it was normal to send personnel to facilities far from the city to manipulate valves or pumps at night and in high-risk areas. Now all facilities inflows and outflows are monitored at any time by the responsible personnel remotely. RealiteQ has provided CAEM the ability to remotely control and manage all their remote assets through a 4G SCADA system. This allows them to better understand and operate the system and provide excellent customer service to their clients. The solution is low cost, robust, comprehensive and easy to set up and use.

Acknowledgement:

I want to thank Mr. Pedro Carrillo from APRA, the end-to-end Solution provider who successfully executed the project and provided me with the data mentioned in this article regarding the project in CAEM.

Author:

Paul Gagliardo, MPH, P.E., is an independent consultant providing advice to firms interested in the municipal water business. He has more than 30 years’ experience in this area. He created and operated a water technology research center in the City of San Diego and directed the Innovation Program at American Water for nine years. He is the host of The Water Entrepreneur podcast.