MULTI/JOINT® 3000 Plus

Description

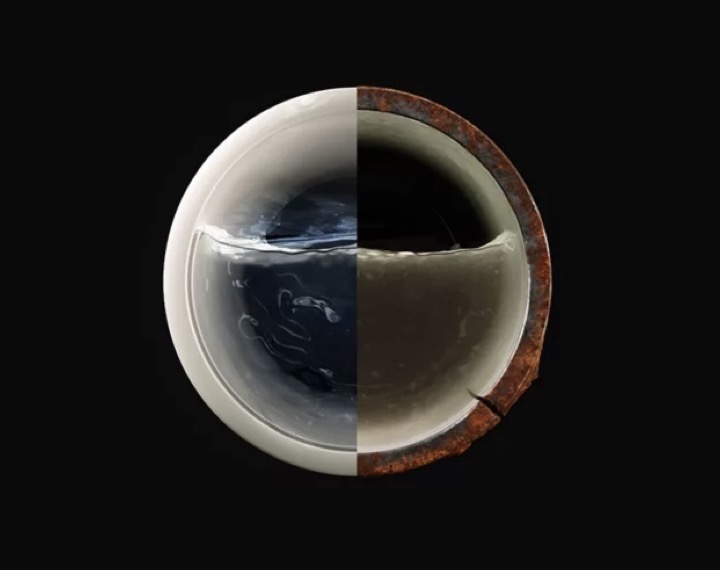

Using the MULTI/JOINT® 3000 Plus system, gas or water pipe networks are quick, safe and simple to connect without the need for special tools. Thanks to the flexibility of MULTI/JOINT® 3000 Plus, meeting the specifications of a wide variety of materials or outside diameters of the pipelines is no longer a challenge. Connections or repairs are carried out by means of a restraint pull-out resistance system. This eliminates the need to work with thrust blocks.

Key features of our pipe connection system

Durable and reliable pipe connections.

MULTI/JOINT® 3000 Plus fittings are suitable for all your water and gas applications. The patented wide range sealing and gripping system is suitable for different outside diameters and various pipe materials.

Unique coating installation

Coating to perfection!

For over 30 years, the MULTI/JOINT® 3000 Plus fittings have carried the GSK approval for its Resicoat® epoxy powder coating. Since 2018, the unique coating has been carried out in-house using an own installation. The on-site GSK approved coating process allows shorter lead times, better quality control, much more flexibility and a significant CO2 reduction.

From assembly to quality inspection

Unique Waga jointing technology.

Renowned as being the best jointing technology for gas and water applications since 1957, the extensive product range is used globally for transport lines, distribution lines, house connections and service lines. The components are produced in various countries, while the final assembly of the fittings takes place in Epe, the Netherlands. Take a look behind the production.