Expansion works at the Burntwood Sewage Treatment Works are expected to complete ahead of time, with two additional treatment stages constructed.

Severn Trent Water contracted RSK Group company MWH Treatment for the upgrade works; the MWH team suggested an early maturation process to keep the project on track so that it could deliver the necessary assets and overall site performance by the regulator date after it experienced delays elsewhere.

A new moving bed biofilm reactor (MBBR) and a tertiary solids removal (TSR) plant have been constructed, with additional primary settlement capacity and new sludge consolidation tanks currently under construction. The works are being carried out as part of the Water Framework Directive to improve the quality of water in UK rivers, lakes and groundwater. The finished works will significantly reduce the biochemical oxygen demand – a way of measuring how much aerobic bacteria is in the water – and dissolved ammonia and phosphorous in the final effluent.

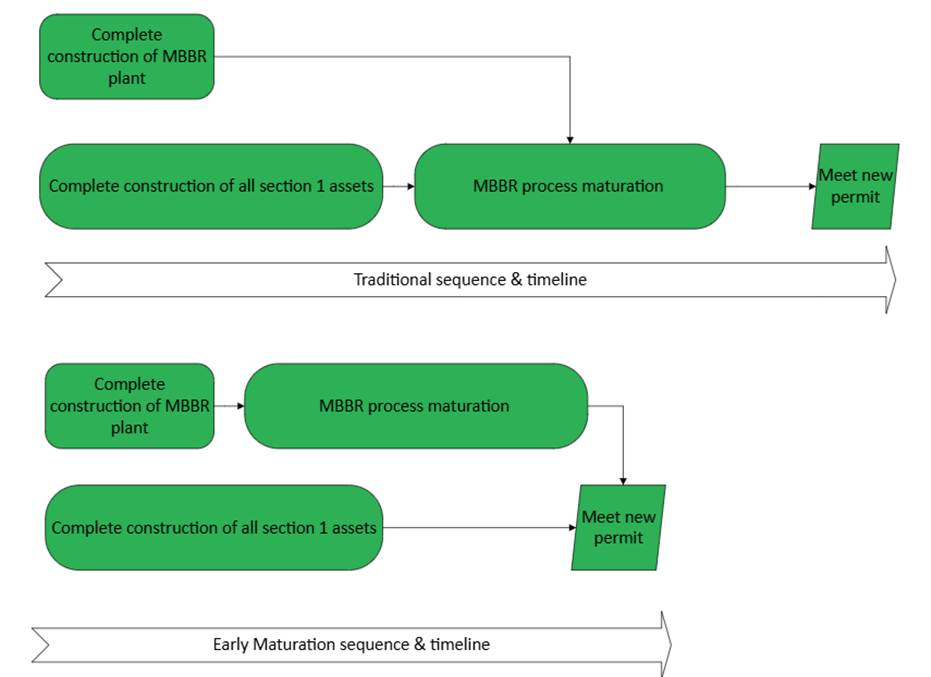

MWH Treatment Project Manager Akram Barkawi said: “Constructing new process assets on a live plant was a particular challenge, but we’ve deployed a new and innovative method of starting the maturation of the moving bed biofilm reactor early. By making use of temporary pipework and pumps to directly connect the existing plant to the biofilm reactor and allowing it to mature while the additional assets were completed, we shortened the overall build time.”

He said that a moving bed biofilm reactor is a wastewater treatment process that uses an aeration tank with plastic carrier where a biofilm can grow. The biofilm removes ammonia from the effluent so that the water being discharged to the watercourse is cleaner.

Akram added: “Usually, you would need upstream works such as the feed pumping station to be completed, as well as the downstream assets to pass flows onto them after it has been through the biofilm reactor. You also need complementary assets such as chemical dosing and drainage to be completed. Dosing is important to improve the settlement and filtration processes and to optimise biological treatment to ensure the discharged water has a balanced pH. Normally, maturation of the biofilm – which takes 10–12 weeks – can start only when all this is done.

“With these additional assets, dissolved solids have longer to settle and the site can meet the tightened regulatory rules around phosphorous and ammonia.”

Along with the new processes, the expanded site required new pipework, ducting, pumping stations and even footpaths and kerbing. MWH Treatment was supported in this by a host of fellow RSK companies; CR Civil Engineering and Hollywood Civil Engineering managed all civil works, including over 3 km of piping across the site, a 16-way ducting system throughout the whole site for electrical feeds and various formed reinforced concrete works such as footpaths, loading bays, plinths and kiosk bases. Nicholas O’Dwyer handled the design, and RSK Geosciences and Ian Farmer Associates handled ground investigations and geotechnical assessments and services. More than 50 people have been working on the site at any one time over the last 12 months. While the new assets are complete, works on-site are expected to continue until the summer to improve the overall performance of the site, Akram said.

Severn Trent Water spokesperson Sophie Tunnicliff said: “The investment at Burntwood Sewage Treatment Works will ensure that we can comply with the new environmental permit conditions that have been set by the Environment Agency. Increasing primary settlement capacity supports downstream biological treatment processes, improving the performance of our existing biological filters, which are now augmented by the new ammonia removal plant. With the new chemical dosing and tertiary solids removal plant, we will be able to reduce the phosphorous being discharged to the watercourse, giving local people a significantly improved natural environment.”