The Swedish firm has delivered a full ATEX SCO 1000 system to Eqinor’s Kårstø processing plant in Nord-Rogaland, the largest of its kind in Europe. The plant plays a key role in the transport and processing of gas and condensate/light oil from major sites on the Norwegian continental shelf.

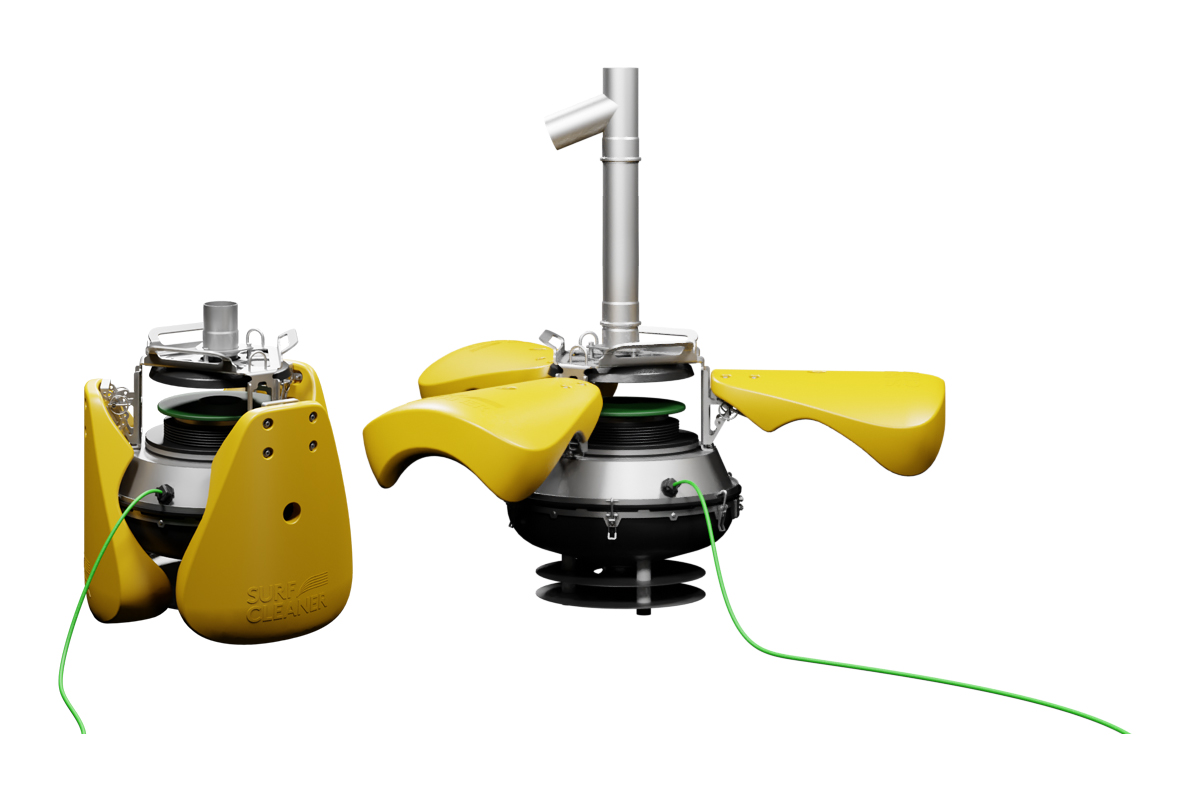

SurfCleaner is the world’s-first skimmer hybrid technology. It is capable of highly effective separation, removal and recovery of floating water contaminants. The core principle behind the technology was developed by clinical physiologist Dr Stig Lundbäck MD PhD following his discovery of the human heart’s Dynamic Adaptive Piston Pump (DAPP) functionality.

Equinor’s refineries, processing plants and terminals transform crude oil and natural gas into everyday commodities such as petrol, diesel, heating oil and consumer-ready natural gas. Around 30 fields are connected to Kårstø via pipelines, and millions of cubic metres of gas and condensate/light oil flow into the plant every day. There, the heavier components are separated out, while the rest, which is called dry gas or sales gas, is piped onwards to the continent. Around 90 million standard cubic metres of rich gas can flow through the plant every day.

At the processing plant, wet gas (NGL—natural gas liquids) is separated from the rich gas and split into products including propane, normal butane, isobutane, naphtha and ethane. Propane is stored in two large rock chambers (caverns) with a total capacity of 90,000 tonnes, while butane, isobutane, naphtha and ethane are stored in tanks. Production of LPG, ethane and stabilised condensate/light oil results in around 500 tanker dockings per year, meaning that the Kårstø plant ranks as the world’s third largest producer of LPG. Meanwhile, dry gas is exported from Kårstø via the Europipe II pipeline to Dornum in North Germany and through the Statpipe and Norpipe pipelines to Emden.

SurfCleaner Founder & Chief Sustainability Officer Christina Lundbäck said the deal marks another significant breakthrough for the firm. “We are thrilled to be expanding in the processing sector across Scandinavia,” she said. “Despite the fact that many processing industries are trying to decrease by-production of wastewater, a vast amount of cooling water and process water still needs to be treated. Some industrial plants use their own specialised facilities to treat wastewater, such as API separators and wastewater process tanks. Others need to transport it to an off-site wastewater treatment plant. SurfCleaner provides effective technology for both situations: Skimmer Separator Hybrids SCO 1000 and SCO 8000 is a highly effective, cost-efficient additions to existing facilities, or they can be used directly onsite to skim, separate and recover all types of oil and floating pollutants from the water surface. The recycled oil is pure and ready to be reused. SurfCleaner’s control system can also be easily integrated with SCADA, providing our clients with process data and traceability.”

The news comes as SurfCleaner prepares to attend the Petroleum Refining Congress, Europe’s largest downstream event for refiners and petrochemical stakeholders, between May 13-15 in Amsterdam, Netherlands.

For more information on SurfCleaner visit www.surfcleaner.com

Related articles:

SurfCleaner lands first South America deal with Aeration Argentina