With headlines like Time magazine’s “ ‘Forever Chemical’ Lawsuits Could Ultimately Eclipse the Big Tobacco Settlement,” it’s no wonder that there is a lot of fear and uncertainty about the legal risks stemming from perfluoroalkyl and polyfluoroalkyl substances (PFAS). The potential liabilities are great, but so too are the technologies being developed to help capture and permanently destroy PFAS, particularly in wastewater.

PFAS were first introduced in the 1940s to make products resistant to heat, water, oil, and corrosion. Their exceptional utility led to explosive development, with about 15,000 compounds created and used in everything from food packaging to touchscreens to clothing.

The problem with PFAS is their toxicity, ubiquity, and seeming indestructibility. PFAS have been linked to a myriad of health problems such as liver damage, thyroid disease, obesity, fertility issues, and cancer. They are dangerous to environmental and human health, yet it’s virtually impossible to escape them. Synthetic chemicals can be found in air, water, soil, and food everywhere in the world. In fact, PFAS have been found in the blood of 97 percent of Americans.

A major mapping project found PFAS pollution in waterways, soils, and sediment at about 17,000 sites in the United Kingdom and Europe. Similarly, 3,186 sites in the United States and the U.S. territories of Puerto Rico and Guam have been found to be contaminated. Industrial wastewater is a major source of PFAS pollution.

The solution to the PFAS problem is twofold: destroy existing PFAS and prevent future usage. However, there is a major hurdle with destruction since PFAS have one of the strongest bonds in chemistry that does not break down naturally, which is why they are commonly called “forever chemicals.”

There are solutions that promise to clear that hurdle. There are a number of new practices and technologies that are being developed that could protect the health and wellness of people and biomes and help allay legal and regulatory risks to industries and municipalities.

PFAS Litigation Is On the Rise

Awareness of the health and environmental damages caused by PFAS pollution has spurred legal action to hold polluters accountable. PFAS litigation started in 2001 with a class-action lawsuit representing 80,000 residents of West Virginia and Ohio over contamination of their drinking water. While that case was settled for $405 million in 2004, it was just the beginning. To date, there have been more than 3,500 personal injury lawsuits leading to settlements totalling $670.7 million.

There also has been a rise in attorneys general filing lawsuits against PFAS manufacturers, with 27 to date. Minnesota was the first and other states have followed suit, including 12 states and the District of Columbia in 2023 alone.

And legal action isn’t just reserved for state courts. In fact, more than 6,400 PFAS-related lawsuits were filed in federal courts between July 2005 and March 2022.

The scope of lawsuits and the size of settlements is raising awareness of the legal risks and the high cost of business as usual. Recent billion- and multibillion-dollar settlements with makers of PFAS have inevitably led to comparisons with Big Tobacco, in which the four largest U.S. tobacco companies agreed in 1998 to pay $246 billion over 25 years to settle cases brought by 46 states, the District of Columbia, and five U.S. territories.

Regulation has great potential to increase liability, especially if the Environmental Protection Agency (EPA) follows through with its proposal to designate two common PFAS compounds — perfluorooctanoic acid (PFOA) and perfluorooctanesulfonic acid (PFOS) — as hazardous substances under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), also known as Superfund. The move is one of the landmarks of the EPA’s PFAS Strategic Roadmap.

Eliminate PFAS In 4 Steps

It’s clear that PFAS regulation and litigation is only going to increase. While still a nascent industry, PFAS management technologies are fast developing to help companies, utilities, and wastewater management facilities. Though found in water, air, and soils, water is one of the first to be tackled. The technologies to eliminate PFAS in water waste streams may differ, but the following four steps will help ensure the effectiveness of responsible PFAS management.

The first step is to utilize comprehensive testing to identify the nature and scope of the PFAS problem. Most commercially available tests use compound-specific LC-MS methods that detect fewer than 40 PFAS compounds. Many destruction methods used today focus on Target Compound Analysis to measure specific PFAS compounds such as PFOA and PFOS, which were the first PFAS compounds to be regulated by the EPA. This process only measures a limited amount of the total PFAS picture. Claros Technologies uses a three-pronged approach to ensure we are accounting for all PFAS in a sample. First, we use Target Compound Analysis paired with non-target PFAS measurement such as EPA’s adsorbable organic fluorine (AOF), draft method. Second, we use a mass-balance equation that measures the total presence of the carbon-fluorine (C-F) bond unique to PFAS. The result is an accurate picture of all PFAS compounds in a sample. Third, it is critical to take a TOF (total organo fluorine) measurement to ensure we are accounting for all fluorines.

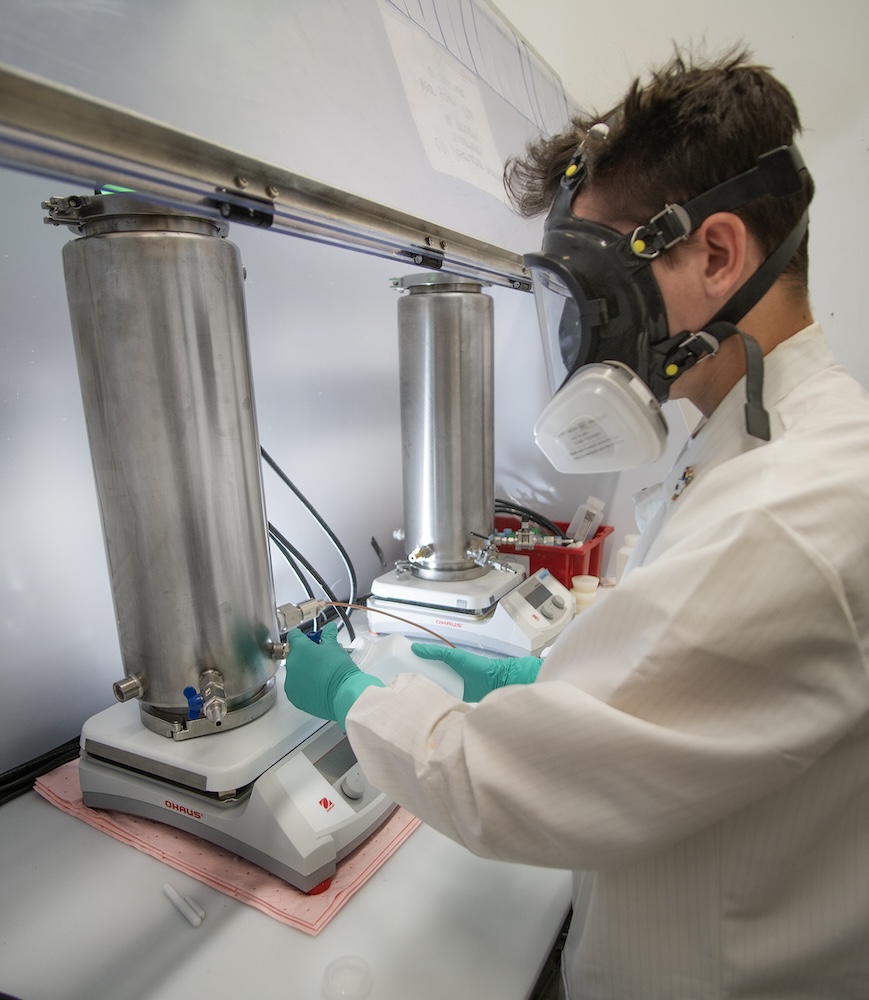

The second step is to capture and concentrate PFAS in wastewater. The most common method currently used to capture PFAS is granulated activated carbon. However, new sorbent technologies are coming to market that could be more effective and more efficient in capturing a few gallons of PFAS concentrate from millions of gallons of wastewater. The new sorbents have smaller footprints, faster empty-bed contact times, and higher loading capacity than traditional methods.

The third step is to permanently destroy long-chain, short-chain, and ultrashort-chain PFAS. Incineration used to be the primary method for disposing of PFAS waste. That method is being phased out since a growing body of research shows that incineration does not fully destroy PFAS, but rather only breaks up long-chain PFAS. The smoke and ash laden with short- and ultrashort-chain PFAS is then spread widely, exacerbating the pollution problem.

There are five prominent new PFAS-destruction technologies being developed to replace incineration: supercritical water oxidation, hydrothermal alkaline treatment (HALT), electrochemical oxidation, plasma treatment, and photochemical defluorination. Each technology uses a different catalyst to break the powerful C-F bond. Supercritical water oxidation and hydrothermal alkaline treatment use hot, pressurized water; electrochemical oxidation and plasma-based water treatment use electricity, and photochemical defluorination uses ultraviolet (UV) light. While it is unlikely that no one technology will work for all applications, photochemical defluorination is emerging as being the low-cost solution with the broadest efficacy.

A proprietary photochemical process developed by Claros Technologies destroys nearly 100 percent of all PFAS compounds, including ultrashort-chain (C1-C3) compounds, in three hours or less. The process has relatively low operational costs because it operates at room temperature and atmospheric pressure. It has a small footprint, can be retrofitted to work with existing filtration systems, and leaves only free fluoride and carbon dioxide, both of which are naturally occurring, nontoxic elements; as well as water that is safe for reuse.

The fourth step is to utilize comprehensive testing to verify total destruction of PFAS. The first three steps are not sufficient. It is imperative to test again to ensure destruction has taken place. However, using only Target Compound Analysis provides a limited amount of data and leaves a critical question unanswered: Were long-chain PFAS compounds simply broken down into short- or ultrashort-chain PFAS? Using Claros Technologies three-pronged testing after treatment accurately measures all the free fluorine to determine what percentage of PFAS was destroyed in the destruction process. Understanding how to measure PFAS compounds is critical to understanding the truth behind destruction claims, which helps safeguard companies or wastewater treatment plants when facing questions by regulators, plaintiffs, or consumers, even in the event that more PFAS compounds are regulated or PFAS are treated as a class.

Managing PFAS Helps Manage Risks

The steady drumbeat of regulation, litigation, and consumer demands for eliminating “forever chemicals” makes it clear that the time has come for effective and proven PFAS management. Acting now to curb PFAS contamination would prove compliance with regulations and help manage legal and reputational liabilities, as well as showcase corporate leadership and stewardship.

Best practices require a four-step strategy: comprehensive testing, PFAS capture, destruction, and comprehensive testing again. This wholesale PFAS-remediation strategy allows for the safe reuse of wastewater, all while protecting human and environmental health. While there are costs to PFAS management, the cost of doing nothing likely would far exceed the cost of adoption.

The power of chemistry may have created the PFAS pollution problem, but chemistry also offers the solutions. Adopting a four-step PFAS management regimen makes it possible to take the “forever” out of “forever chemicals” and successfully transition to a circular economy.

John holds a PhD in Biosystems Engineering from the University of Minnesota. His expertise includes the development and application of nanomaterials in environmental systems. John serves as a Director of Research and Development for Claros, where he directly oversees product development, sustainability, and research activities.

Related articles:

Destroying PFAS once and for all