John McConomy, Commercial Director of OxyMem

John McConomy, Commercial Director of OxyMem speaks to H2O Global News about climate adaptation and how his company is responding the challenge.

Climate change is water change. Do you agree?

Absolutely, this is undeniable. Looking across the globe not only can we see increasing drought conditions brought on by record high temperatures, but also the destructive impact of flooding. The challenge of increasing water scarcity is compounded by the simultaneous growing demand for water. Climate change is the root cause of this chaos in our water systems and we need to adapt to ensure that water and sanitation is routinely accessible for everyone.

How do you think climate change will impact your business?

The wastewater water treatment sector accounts for perhaps up to 3% of a developed country’s energy consumption. As legislation tightens and environmental pressures call for improved discharge water quality, I see a growing need and thus demand for energy-saving technologies that can help us lower emissions and achieve important net zero goals.

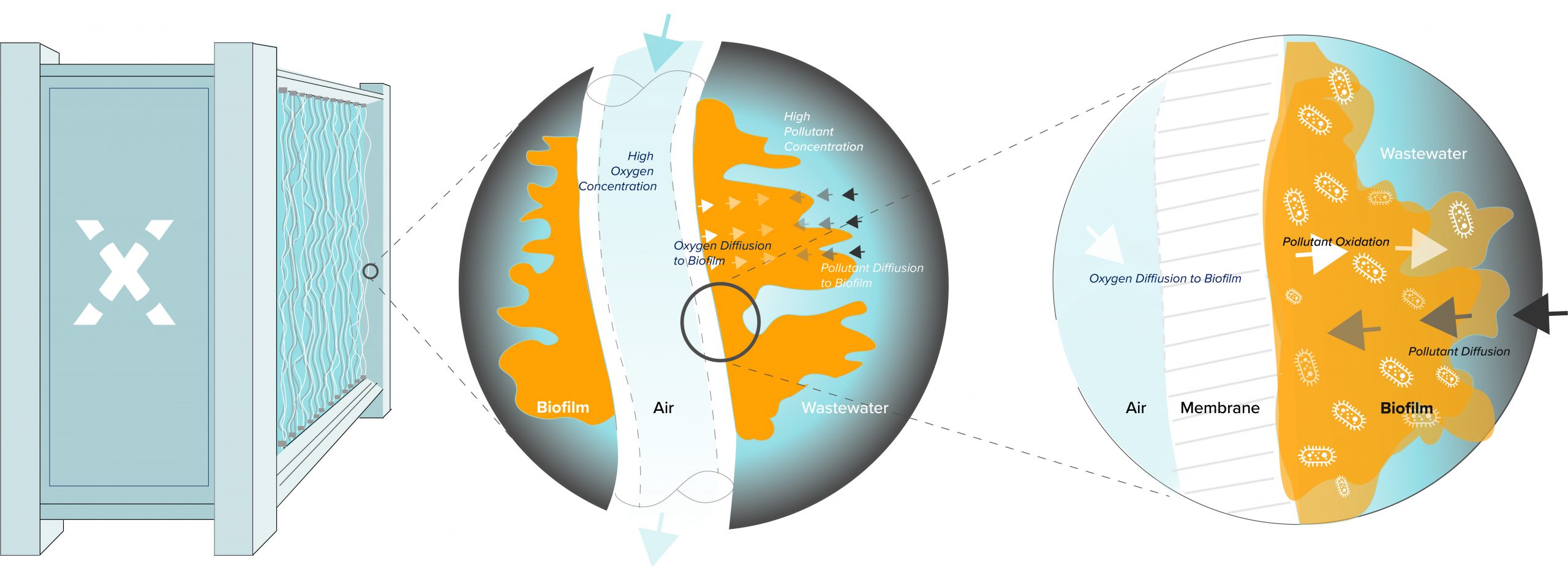

For example, membrane aerated biofilm reactors (MABRs) can allow wastewater treatment plants to dispense with energy-intensive treatment solutions, expand their treatment capacity achieve improved nutrient removal – when compared to standard go-to process intensification technologies, DuPont™ OxyMem™ drop-in MABR modules can save in the region of 90% on energy consumption.

Thankfully there is now also a growing awareness of the real danger posed by nitrous oxide emissions from treatment plants. This harmful greenhouse gas has a global warming potential 300 times worse than carbon dioxide and is the world’s largest man-made ozone-depleting substance. Bubbles have been used as a means of transferring oxygen to biological reactors for nitrification over the last 100 years and these tend to exacerbate the release of nitrous oxide. One of the great things about MABRs is that the denitrification and nitrification processes are contained within the biofilm, providing for a ‘bubbleless’ solution, meaning that nitrous oxide emissions are an order of magnitude lower. There are a number of parallel studies ongoing to help quantify the true potential nitrous oxide savings of MABR.

What water technologies do you currently use?

OxyMem™ pioneered the commercial development of Membrane Aerated Biofilm Reactors (MABRs), originating as a spin-out from the University of Dublin where our founders have been involved in biofilm research for decades – they still practice and support global biofilm research today as part of the faculty. Our latest drop-in modules mean that owners and operators can easily boost the treatment capacity of legacy wastewater treatment infrastructure within an existing footprint – in addition to being an easy means of enhancing capacity, this solution may prove to be the only means of upgrade for many global sites where population growth and urban expansion has resulted in older activated sludge plants being landlocked, having no space available for traditional expansion.

The modular design means that we can provide incremental expansion, and a 10-20% uplift in capacity is generally easy to achieve without any reworking of procedures or additional infrastructure – to improve nitrification our MABRs may be dropped into live anoxic zones without any interruption to operations.

Since becoming part of DuPont we’ve been able to offer even greater value to our customers, providing a one-stop shop for different water technologies, and helping them build multi-technology solutions to fit their specific needs. For example, an OxyMem™ MABR might be paired with ultrafiltration or reverse osmosis systems from other DuPont businesses, allowing us to create a multi-technology solution that treats water to a standard where it is suitable for reuse.

What are some of the barriers to the adoption of your technology? Are there any barriers?

One of the great benefits to OxyMem since becoming part of DuPont has been how our colleagues in the wider business have been able to help us broaden our audience and introduce more people to the technology and what makes it unique. Additional speaking opportunities such as within the DuPont webinar programme allows us to reach a larger number of people around the world.

While awareness and adoption continues to grow globally, there is still a lot of work to do to improve understanding of Membrane Aerated Biofilm Reactor (MABR) technology within the sector. It may seem strange, but even the name that was adopted by the scientific community decades ago is one hurdle that raises it’s head quite often. The initials MABR can generate a level of confusion in the market, as it can be lost within the alphabet soup of other available water technologies owners might also be considering, such as SBR, MBR and MBBR. It takes a while for engineers and plant owners to appreciate that although MABR is a new and distinct technology, it is not an “all or nothing” competitive solution. MABR lends itself extremely well to complementing most existing technologies that could also be used to treat wastewater; for the most part the installation of OxyMem™ MABR could be considered a means of turbo-charging any biological treatment plant, existing or new build. Various upgrade arrangements are available and it could well be the case that an MABR-CAS hybrid solution proves the optimum design for a treatment plant owner.

Perceived risk is another aspect we need to overcome with a new technology. Despite decades of research and commercializing a field scale MABR solution over a decade ago, the technology is still seen as new by most, and with that comes some concerns around risk. We work closely with an extensive list of global engineers and owners to walk through all perceived risks they may have, environmental, operational and commercial. While building a robust evidence base, at OxyMem™ we strive to de-risk the proposition for our customers, which should allow them to access benefits of the technology much sooner. For example, rather than having to drain tanks and change an existing treatment solution to 100% OxyMem™ MABR, the modular nature of our product means that owners can easily deploy a few units as a permanent upgrade solution or perhaps conduct a full-scale trial to build their confidence and then expand to meet the total desired treatment capacity. With no change to the existing infrastructure or processes, most upgrade deployments are easily reversible if for some reason an owner wishes to revert back to what they had yesterday – having said this no client has wanted to send our equipment back and those who start with smaller scale demos or trials often obtain desired results and simply continue on their MABR journey with a higher level of confidence.

What role should government play in promoting climate adaptation tech?

We rely on governments to create economic environments that encourage innovation and the widespread adoption of new technology. We must make use of all of the various tools at our disposal to address the impact of climate change on water availability and reduce the water industry’s environmental footprint.

In the UK, the water regulator Ofwat has been doing some excellent work fostering innovation and encouraging greater collaboration as the industry seeks to deliver on its net zero goals. Our OxyMem MABR technology is part of a transformative Triple Carbon Reduction project led by Anglian Water which received more than £3.5 million of funding from Ofwat. This collaboration aims to assess MABR as a treatment solution that can help the sector reduce water treatment greenhouse emissions and electricity use. At the same time the project will also evaluate a renewable source of green hydrogen and assess potential repurposing of oxygen as a byproduct – the hope is to end up with a scalable solution that can be upscaled and deployed across the rest of the UK water sector.

If you could make one type of water innovation mainstream overnight, which would it be?

We are only just scratching the surface of the potential of Membrane Aerated Biofilm Reactors (MABRs) and I’m excited to see what the future holds as we introduce more people to its benefits. You could liken MABR to where MBR was over 20 years ago in terms of performance and market adoption; with adoption accelerating month by month, it is crystal clear to us where MABR is heading globally.

We know OxyMem’s drop-in MABR modules can typically provide in the region of 10-20% upgrade to a majority of activated sludge plants without us even having to look at the numbers too closely, and without the need for additional infrastructure or changes to processes, but if given free rein to rework how an existing plant operates, where a client had confidence and the desire push the performance and sustainability envelope, the technology has the ability to biologically treat multiples of the incoming load within an existing footprint on some plants. This is evident when we run newbuild designs and offer our OxyFILM™ arrangement, we can provide clients with plant designs approximately 5 times smaller in footprint than traditional systems and consuming 4-10 times less energy.

Given the positive impact low energy, sustainable solutions can have in today’s world, one of the greatest immediate potentials for MABR lies in how quickly and easily plants can be upgraded or built new. Rather than spending years procuring and preparing land only to then build substantial civil structures and implement older technologies which will create avoidable emissions for the next 30+ years, the quality of effluent being returned to our environment could be improved with prompt deployment of up-to-date technology and the construction of much smaller, sustainable treatment facilities. With greenhouse gases such as nitrous oxide which are hugely detrimental to our planet remaining in our atmosphere for a long time once released, you would agree the quicker we can reduce emissions from wastewater treatment plants the better for us all. Time is not on our side.