Thomas Walski, Ph.D., P.E.

Senior Product Manager, Water Infrastructure

Bentley Systems, Inc.

Thomas has 40 years of experience in applied hydraulics. He is the author of hundreds of journal papers and conference presentations, and is the author and co-author of several books.

He has won numerous awards for his work, including the best distribution and plant operation paper in the Journal AWWA on three occasions. In addition to developing software, he has served as a distribution system operations manager, engineering manager for a large water company, executive director at a regional sewer system and a university professor.

In the water sector, everywhere you turn, you hear or read about digital twins. The first concept of digital twins has been around since the dawn of the millennia, but it wasn’t until the last decade that digital twin technology really took off. Digital twins have changed the way the data are collected, managed and leveraged by water and wastewater systems.

We spoke to Tom, to find out more about how digital twins can improve efficiency and non-revenue water with improved visibility of data and analytics.

“People have been successfully running water distribution systems for more than 150 years. In the beginning, everything was done manually, but gradually automation in one form or another has made it easier to run systems.

With the coming of computers in the 1960s, the operation of water systems has gotten easier, but it’s not just easier, it’s better. Digitalization of water systems has been sneaking up on the industry for years. We can run systems more efficiently, detect and correct problems quicker, and have solid numbers to support our decisions. A digital twin is just one step along the way to making better decisions in the face of increasing challenges and decreasing funds.”

What are digital twins?

The AWWA and SWAN definition is “A dynamic digital representation of real-world entities and their behaviors using models with static and dynamic data that enable insights and interactions to drive actionable and improved outcomes.”

You can think of the digital twin as the digital representation of the physical system. This distinguishes the digital twin from a CAD or GIS display in that it not only looks like the real system but behaves like the real system. In some ways, the water industry has been using digital twins for years, but it has only in recent years been recognised.

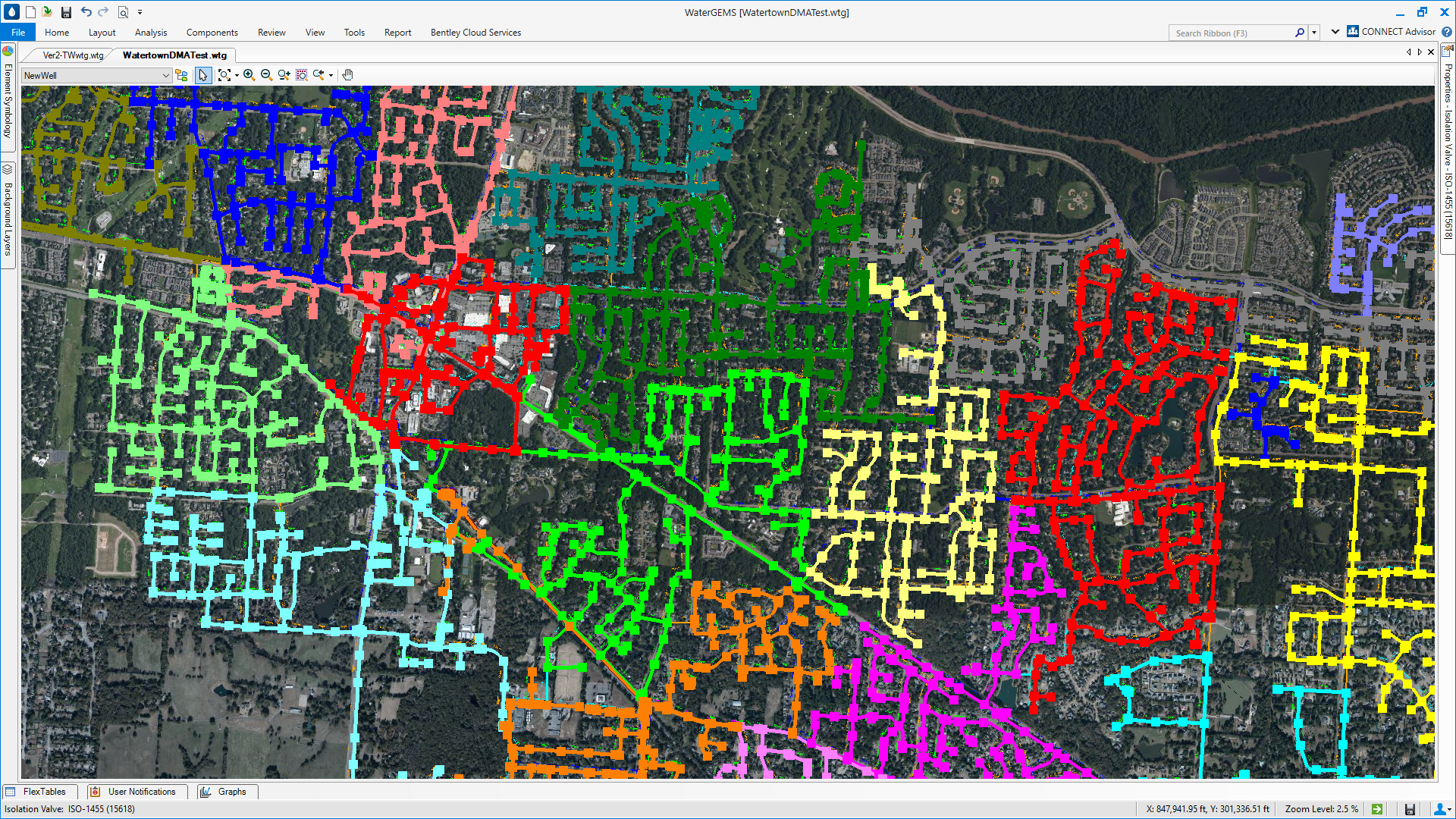

Photo courtesy of Bentley Systems

Why would a water or wastewater utility want to get involved with a digital twin for their water distribution system?

One of the key features of most digital twins is their ability to share data across different data silos in the utility. Quickly and smoothly moving data between teams enable them to cooperate more easily to solve or prevent problems. GIS, SCADA, hydraulic modelling, CMMS, and other systems have their own ways of communicating and one of the key purposes of a digital twin is the ability to share data between the different technologies.

Once data are shared, opportunities for improved workflows arise. As we get better at modelling the behaviour of system components, it’s much easier to try different “what-if” scenarios to arrive at the best solution to a problem.

How did digital twins sneak up on people?

It’s hard not to have come across the term “digital twin” in the water industry in the past few years. It would be easy to ignore it as a marketing buzzword, when it is really a paradigm-changing technology. Now is the time to get on board with digital twins.

Is there a standard template for a digital twin?

Every water and wastewater system has its own issues, products, organisation and priorities. A digital twin does not need to be completed all at once in a one-size-fits-all procedure. It’s best to start with the components that are the most pressing problems and have the most reliable data.

Photo courtesy of Bentley Systems

What is Bentley’s contribution to digital twins?

At Bentley, we provide innovative software to advance the world’s infrastructure. We work with digital twins for roads, structures, energy and cities among other industries. By having the core technology, we don’t need to reinvent the wheel for each industry.

The core technology is Bentley’s iTwin platform. This is an open, scalable cloud platform for digital twins of infrastructure assets. iTwin provides instant access to large-scale datasets for visualisation and insights. Digital twins are continuously synchronised and federated across repositories on their native formats while supporting complex workflows including those for water distribution, wastewater collection, and treatment plant asset performance management.

What specific capabilities can Bentley deliver in the water space?

We provide a fairly complete set of tools including real-time simulation modelling, system monitoring, energy reduction at pumps, non-revenue water reduction, incident tracking, water balances, emergency response, tank monitoring and turnover, customer meter analytics, and capital planning for pipes. We also provide the ability to use Power BI to view data associated with the digital twin to build custom reports.

Who is the intended audience for a digital twin in a water utility?

Everybody. The digital twin provides a way to share data between individuals and departments within the utility and any external consultants. Operators can check energy use; engineers can view SCADA data to track the system; managers can view work orders, just to name a few examples.

Photo courtesy of Bentley Systems

Why is sharing data so important to water utilities?

Utilities are tracking more and more data all the time, but a digital twin can convert that into actionable decisions. A utility that can track and share quality data has a much better basis for supporting decision-making.

We hear a lot about “breaking down data silos.” What does that mean?

Suppose an engineer in the past needed some SCADA data to calibrate a hydraulic model. That data would be stored in the SCADA silo, and only a handful of people (or maybe only one person) could retrieve that data. That person would usually be very busy and retrieving the data manually would be tedious.

A week later, the engineer would call again and ask for the data, but it wouldn’t come, or it might come, but it would not be exactly what the engineer needed.

Ultimately, the data would sit in its own silo unused, and the engineer would need to make do without it.

When will we be done with digital twins?

Never. It will evolve as more computing power and data become available and improved analytical techniques are developed. Maybe digital twins will become “super twins” or “perfect water” but digital twins will continue in some form.

How can someone find out more about Bentley’s solution for water?

A good starting point is Bentley’s iTwin Experience at https://www.bentley.com/software/openflows-watersight

By implementing Bentley’s digital twin technologies like Bentley’s OpenFlowsTM powered by the Bentley iTwin® platform, water utilities can utilise the potential of their data and unite legacy data with operational and engineering data for a greater understanding of their water system.

We know that sooner or later, digital twins will become a vital part of every water utility control room and a “new normal” for water utilities to improve the reliability of water systems and reduce operating expenditures, lessen their environmental footprint, and provide customers with safe and efficient water services.

Read more from Bentley Systems:

Bentley Systems Announces Michael Campbell Joining as Chief Product Officer

Bentley Systems Announces the Finalists in the 2022 Going Digital Awards in Infrastructure