The International Energy Agency (IEA) says we must double hydropower capacity by 2050 if we are to meet the Paris climate targets. However, many existing hydro facilities in the US and Europe are old, and there are few options to build new ones.

The answer? Refurbish existing facilities to make them more efficient, increase output, further their lifespan – and reduce maintenance requirements in the process.

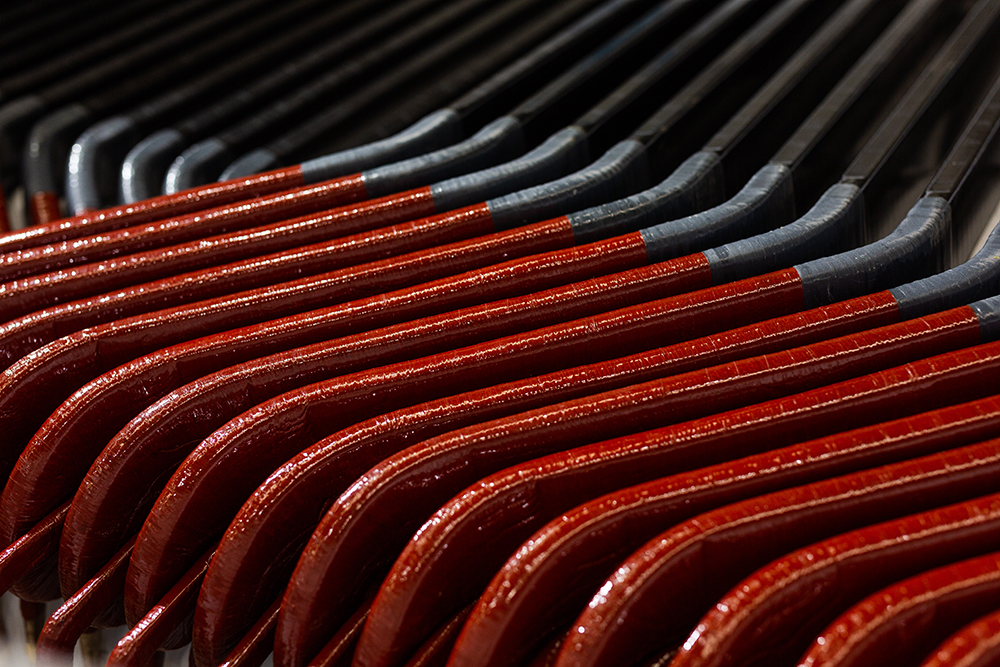

The first port of call is the generators. The beating heart of a hydro plant, well-maintained and properly equipped generators are critical to the overall efficiency of a power plant. One of the most essential components of the generators are the high voltage coils or stator windings.

Hydro generator insulation systems have a finite life and generally need to be rewound after 40 to 50 years. Using the right coils is a critical part of this job and can help energy companies meet or exceed their efficiency targets.

Preformed Windings is a global leader in the supply of high-quality diamond coils to the hydro industry.

They have spent more than 15,000 hours of R&D on their QualCoil range of high-voltage diamond coils, building-in longevity, and the lowest partial discharge rate in the industry.

“We must generate clean energy and move away from fossil fuels but building new hydro plants is expensive and a very long process” said Preformed Windings Global Sales and Marketing Director, James Stevens.

“Installing new high-quality coils is one of best and most cost-effective ways to increase the lifespan of existing facilities, improve efficiency, and reduce maintenance requirements.”

Preformed Windings QualCoil coils can be found in hydro facilities across the globe, helping to bring power to over 25,000,000 homes.

A testament to their superior product, the company gives their customers up to 10 years warranty on their QualCoil coils.

While a product manufacturer by trade, Preformed Windings has an open door policy, working with their customers, suppliers, industry experts, associations and public institutions to create coils that are more efficient and ultimately help pave the way to net zero.

Global commodity leader, GE Renewables, one of Preformed Windings loyal customers, explains:

“Preformed Windings have supplied many sets of high voltage coils to GE Renewables over the years. The quality of product and service is exceptional, and they are a trusted partner in our supply chain.

“We enjoy collaborative and cutting-edge research and development with Preformed Windings, which positions both organisations as thought leaders in the hydro industry.

“Their products offer significant benefits such as very low partial discharge and a long service life.”

Click here to find out more about Preformed Windings.

Do you have an article or video that you would like to contribute? Submit your contribution here or keep up with the latest news from the water industry and wastewater industry by subscribing to our weekly newsletter