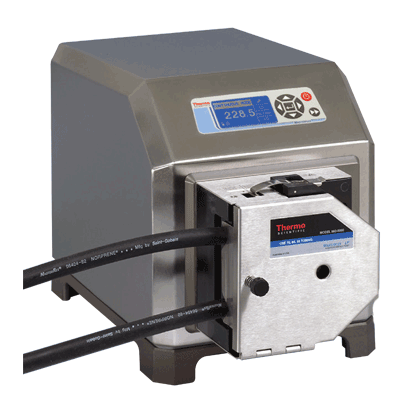

Peristaltic Pump

Description

A peristaltic pump, also known as a roller pump, is a versatile and reliable type of positive displacement pump widely used across various industries. This pump utilizes a flexible tube and rollers to move fluids, mimicking the natural peristaltic movement seen in biological systems like the gastrointestinal tract. This feature makes peristaltic pumps indispensable in applications where precision, sterility, and contamination prevention are crucial.

How It Works

The core component of a peristaltic pump is its rotor, equipped with rollers or wipers attached to its circumference. As the rotor turns, these rollers compress the flexible tube, creating a squeezing action that propels the fluid forward. The section of the tube under compression is sealed off, forcing the fluid to move through the tube toward the outlet. When the rollers move past the compressed section, the tube returns to its natural state, drawing more fluid into the pump. This continuous process ensures a steady and controlled flow, making peristaltic pumps highly effective for both continuous and intermittent pumping tasks.

Applications

Medical and Biopharmaceuticals

In the medical and biopharmaceutical fields, peristaltic pumps are essential for processes requiring absolute sterility and precision. During dialysis, these pumps transport hemoglobin and other fluids with minimal contamination risk. They are also used in surgeries, particularly in heart-lung machines to circulate blood during cardiopulmonary bypass. Their ability to handle IV fluids through infusion devices without contamination makes them invaluable in various medical procedures.

Water Treatment

Peristaltic pumps play a crucial role in water treatment processes, accurately dosing chemicals such as chlorine and sodium hypochlorite. The precise dosing capability ensures the correct amount of chemicals is added, enhancing treatment effectiveness. These pumps also add flocculants, which help remove impurities from water, thereby improving water quality. Their ability to handle reactive chemicals without contamination or component degradation makes them ideal for these applications.

Industrial

In industrial settings, peristaltic pumps handle a wide range of fluids, including viscous or particulate matter-laden fluids. In the mining industry, they transfer abrasive slurries such as lime milk. Their robust design and ability to prevent fluid contamination make them suitable for transporting chemicals in manufacturing processes. Additionally, the pumps' precision in metering and dosing is valuable for applications requiring exact fluid quantities, such as pharmaceutical and cosmetic production. The durability and reliability of peristaltic pumps ensure consistent performance even under demanding industrial conditions.

Food and Beverage

Peristaltic pumps are widely used in the food and beverage industry due to their sanitary design and ability to prevent cross-contamination. These pumps are ideal for transferring and metering ingredients such as flavorings, colorings, and additives. Their gentle pumping action maintains the quality and integrity of the product, preserving the taste and texture of food and beverages. The ease of cleaning and maintenance further enhances their suitability for applications where hygiene is paramount. By using appropriate tubing materials, peristaltic pumps can handle various food-grade fluids, ensuring compliance with industry standards and regulations.

Advantages

Contamination Prevention

Peristaltic pumps' primary advantage is their ability to prevent contamination. Since the fluid only contacts the pump’s tubing, contamination risk is eliminated. This is critical in the medical, biopharmaceutical, and food industries, where maintaining sterility is essential. The airtight system of peristaltic pumps ensures no external contaminants enter the fluid stream, making them suitable for handling highly reactive or sterile fluids.

Chemical Compatibility

Peristaltic pumps offer exceptional chemical compatibility because only the tubing needs to be compatible with the pumped fluid. This simplifies maintenance and reduces the need for frequent testing of seals, O-rings, and valves. By choosing the appropriate tubing material, these pumps can handle a wide range of chemicals, from highly corrosive acids to delicate biological fluids. This versatility makes them a preferred choice in industries that deal with various chemicals and require reliable and consistent performance.

Handling Viscous and Particulate Fluids

Peristaltic pumps excel at moving thick, viscous fluids and those containing particulates, bubbles, or trapped gases. This capability is essential in industrial applications where such fluids are common. The pump design ensures fluid is transported without causing damage or degradation, making them suitable for handling abrasive slurries in mining operations or transferring thick cosmetic lotions. The ability to handle fluids with varying viscosities and particulate content without clogging or efficiency loss is a significant advantage in many industrial processes.

Considerations

While peristaltic pumps offer numerous benefits, there are a few considerations to keep in mind:

Tubing Wear

Continuous squeezing of the tube results in gradual wear. Regular monitoring and timely replacement of the tubing are necessary to maintain optimal performance. The rate of tubing wear depends on factors such as the type of fluid being pumped, pressure, and frequency of use. Implementing a routine maintenance schedule can help identify and replace worn-out tubing before it affects the pump’s efficiency or causes a breakdown.

Power Consumption

The drive motor is under constant load to maintain squeezing pressure on the tube, leading to higher power consumption compared to some other pump types. This increased power usage is a trade-off for the pump’s ability to handle a wide range of fluids and maintain consistent flow rates. When selecting a peristaltic pump, it is essential to consider the power requirements and ensure the benefits of the pump’s performance outweigh the operational costs.

Conclusion

Peristaltic pumps are a robust and versatile solution for a wide range of fluid handling applications. Their unique design ensures contamination-free operation, making them indispensable in medical, biopharmaceutical, industrial, and many other fields. With their ability to handle viscous and particulate-laden fluids, precise flow control, and ease of maintenance, peristaltic pumps are a reliable choice for any application requiring clean and controlled fluid transfer. Whether used in delicate medical procedures, demanding industrial processes, or hygienic food and beverage production, peristaltic pumps deliver consistent performance and peace of mind.

About us

Harrington is the nation’s largest distributor of plastic piping systems. Since opening Harrington has greatly expanded;now with over 60 locations, we have increased our reach from the West Coast to Florida, throughout the New England states, and Hawaii. Harrington is a trusted leader in offering versatile products to meet the needs of a multitude of processes and applications.

Harrington’s focus on industry requirements, high standards of quality products, a dedicated, technically oriented staff, and serviceability in virtually every major market area in the United States have all contributed to the success that we see today.

All of our facilities house inventories that include PVC, CPVC, PVDF, Polypropylene, fiberglass, and plastic-lined steel, as well as all of the components for a complete system such as tanks, grating, pumps, and instrumentation.