With climate change, aging infrastructure, design flaws and increased regulatory pressure, it’s crucial for companies operating and maintaining dams and levees to seek more effective and efficient ways to keep a close eye on the condition of these critical infrastructures. Dam safety engineers need to be on the lookout for early signs of potential structural issues or environmental effects.

To get a better grasp of the latest trends and practices in condition monitoring, Bentley Systems partnered with ThoughtLab to conduct a global survey in the first quarter of 2023. The survey reached out to 500 companies involved in monitoring dams, mines, and bridges, as well as infrastructure engineering, public and private development, and environmental services. The respondents included top-level executives, senior managers, and technical experts familiar with condition monitoring in their respective organisations. These professionals came from various sectors and were located in five different countries, with companies ranging in size from less than 100 employees to more than 1,000.

The study revealed that automation is gaining ground in the field of condition monitoring for natural and built environments, and companies are increasingly adopting connected sensor technology to monitor in real-time and to reduce the need for laborious and hazardous manual inspections.

The Shift from Manual to Automated Monitoring

Transitioning from manual to automated monitoring isn’t solely driven by the need to meet stakeholder and regulatory requirements. It can also yield substantial cost savings and enhance an organisation’s return on asset investment, as well as improve the culture of innovation and collaboration within the organization aiding in more effective decision-making processes.

With the minimal cost disparity between manual and automated monitoring, only 28% of dam monitoring in 2023 are fully automated and 79% of dam owners rely on Excel as their primary data management tool. While manual monitoring decreased by 21% in the past two years, 16% of organizations who continue to rely on manual methods, mistakenly perceive automated condition monitoring as the more expensive option compared to manual methods. However, it has been proven that once you’ve initially invested in automated systems, the ongoing expenses tend to be lower than those associated with the labour-intensive manual approach.

When assessing expenses, many organisations often overlook the strategic and intangible benefits of automation. These include the potential avoidance of catastrophic losses stemming from legal actions, fines, and stock price downturns resulting from incidents that occur and that manual monitoring did not find. Therefore, embracing this shift can have substantial benefits.

The Benefits of Automated Monitoring

Automated monitoring offers numerous advantages over manual methods. For example, it enables decision-makers, from engineers to C-level executives, to have a holistic view of the dam’s conditions, facilitating timely and informed decisions. By quantitatively measuring risks and continuously monitoring key parameters, organisations can proactively identify potential issues and take necessary measures to mitigate risk.

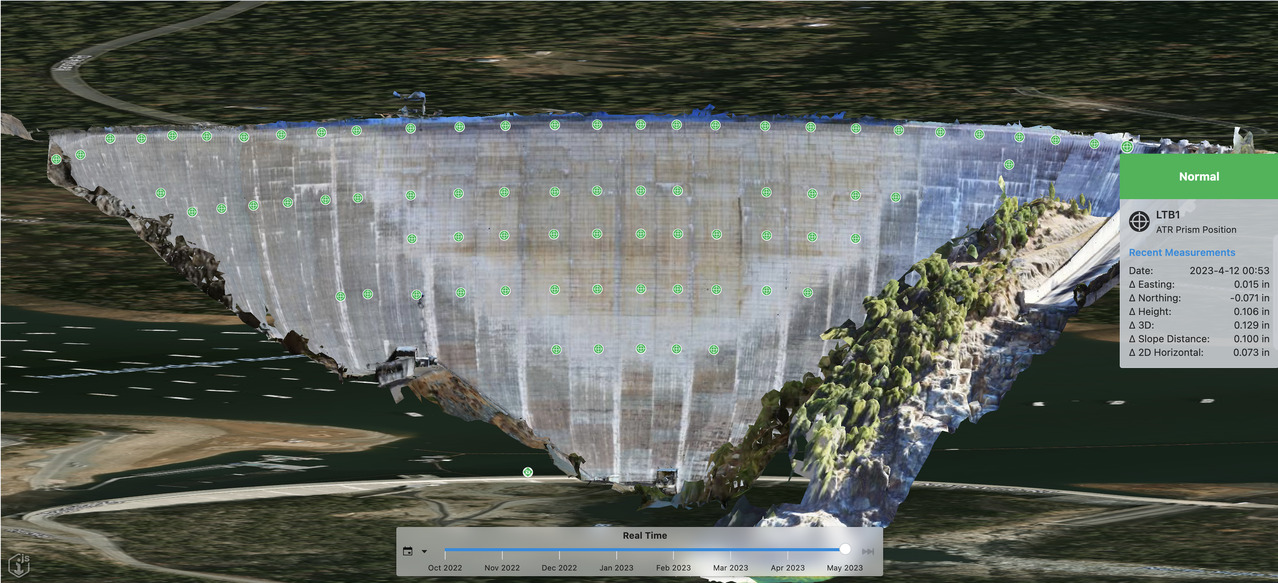

One of the latest trends is to combine condition monitoring with digital twins for increased visualisation and situational intelligence. A digital twin is a virtual model of an asset, created using real-world data collected from sensors or network-connected equipment, and the use of such technology is gaining traction in the field of automated monitoring. By integrating condition monitoring data with digital twins, organisations gain a deeper understanding of their infrastructure, detect variations from expected trends, and make faster and more accurate data-driven decisions.

Case Study: New Bullards Bar Dam

To illustrate the advantages of automated monitoring, we can examine the case of the New Bullards Bar Dam. Managed by Yuba Water Agency in California, this concrete-arch dam stands at an impressive 645 feet and serves multiple purposes, including flood mitigation, hydroelectric power generation, and water supply for nearby communities.

In late 2022, the Yuba Water Agency embarked on a digital transformation journey, leveraging digital twin technology to revolutionise their monitoring practices. Committed to dam safety and efficient, reliable infrastructure operations, Yuba Water sought to modernize the dam monitoring system by collecting continuous, real-time operational data. The implementation of automated monitoring led to a significant reduction in risk exposure and an improvement in overall safety standards. The digital twin approach enables a 1,000-fold increase in data points, providing a comprehensive understanding of the dam’s functionality and facilitating proactive decision-making. Furthermore, the accuracy of data collection improved by 50% compared to manual methods.

“The Bentley solution has reduced the cost and time associated with getting data from the monitoring system,” said Tim Truong, Chief Dam Safety Engineer, Yuba Water. The original legacy system took approximately one week to get a data point from a target and cost USD 5,000 for each manually collected data event. The new cloud-based system can collect a data point from over 80 prisms twice a day and make it immediately accessible to the authorized users at no extra cost other than the purchase of the iTwin software. It has saved hours every week and improved workflows and productivity, all while eliminating risky on-site visits.

Compared to a conventional monitoring system, the digital twin has significantly improved data accuracy and risk assessment, allowing the team to closely monitor the structure, working toward the agency’s ultimate goal of ensuring public safety and protecting the surrounding environment. Using iTwin IoT, the dam is monitored more closely and quickly during heavy rainfall and seismic events. “For Yuba Water Agency, there is nothing more important than public safety. Investing in a real-time, automated total monitoring station at New Bullards Bar Dam significantly improves our monitoring capabilities and is testament to our continued commitment to public safety and infrastructure resilience,” said Truong.

Overcoming Challenges in Automated Monitoring

Implementing remote, automated monitoring systems comes with its own set of challenges. Many organisations lack knowledge about the latest technological and IoT solutions, and some parameters may not have commercially available sensing solutions. Custom engineering, including the design of enclosures, power systems, and communication infrastructure, may be required to adapt off-the-shelf components to specific monitoring needs.

Integration and compatibility issues between different sensor systems and data management software can also pose obstacles. The expertise of specialist consultants or providers is crucial in navigating these challenges, ensuring the seamless integration of various technologies and sensors. Additionally, these experts can assist in sourcing and modifying sensing components and establishing effective data transmission and interpretation systems.

To extract maximum value from automated monitoring systems, organisations need to leverage advanced data analysis techniques. While generic software tools like Excel, Tableau, and PowerBl are commonly used for data analysis, they may not be suitable for today’s real-time monitoring, alerting, and decision-making needs. Digital twins offer an ideal platform for integrating and analysing data from various sources, enabling meaningful insights and actionable intelligence.

The Future of Condition Monitoring

In the realm of condition monitoring, fully automated organisations are racing ahead of the pack, leaving those who haven’t embraced full automation trailing in their wake. Over the past couple of years, a whopping 82% of fully automated organisations have broadened their monitoring capabilities and services, whereas only 54% of those relying mostly on manual methods have done the same.

What’s really fascinating is that companies opting for full automation in their condition monitoring can carry out more advanced analyses and correlations across extensive datasets. This empowers them with a comprehensive 360-degree view of performance, fulfilling the increasing demands of stakeholders and regulators for greater transparency.

Consequently, fully automated firms are better equipped to ensure both environmental and structural safety, reduce risks, and promptly address any issues that crop up.

Conclusion

In conclusion, the latest trends in condition monitoring reveal a marked distinction between organisations that fully embrace automation and those primarily relying on manual processes.

Firstly, fully automated companies have a clear edge as they effectively track a wider range of built and natural systems. Notably, they display a heightened focus on monitoring structural, geotechnical, geospatial, meteorological, as well as surface water systems. Furthermore, these organisations excel in their ability to seamlessly integrate sensor data with additional information sources, offering them the means to maximise the value derived from their condition monitoring programs.

These organisations effectively surmount the challenges associated with transitioning to automated condition monitoring, which may include technological limitations and knowledge gaps in telemetry or hardware installation. They often collaborate closely with ecosystem partners and consultants while ingeniously employing available sensors that correlate with hard-to-detect parameters.

Overall, these latest trends underscore the clear advantages and distinctive practices of organisations that fully embrace automation in condition monitoring, paving the way for improved efficiency, deeper insights, and the ability to overcome evolving challenges in this dynamic field.

Learn more about the latest trends in condition monitoring in the 2023 Condition Monitoring Report and understand how organisations are adopting digital twins and automated condition monitoring in Bentley Systems Dam Monitoring Solution.

By Murray Fredlund, Senior Strategic Advisor, Geotechnical, Water, at Bentley Systems